2023 Volume 8 - Issue 1

-

January 23, 2023 Research Article

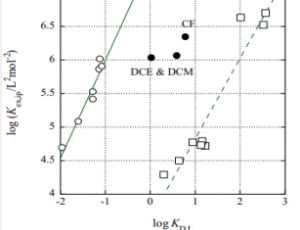

Abstract Extraction of Ca(II) picrate (CaPic2) and SrPic2 with 18-crown-6 ether (18C6) and benzo-18C6 (B18C6) into 9 diluents were studied at T = 298 K. Their ion-pair extraction constants (Kex,ip = [MLPic2]org/[ML2+][Pic-]2) were determined at M = Ca, Sr, L .....

Abstract Extraction of Ca(II) picrate (CaPic2) and SrPic2 with 18-crown-6 ether (18C6) and benzo-18C6 (B18C6) into 9 diluents were studied at T = 298 K. Their ion-pair extraction constants (Kex,ip = [MLPic2]org/[ML2+][Pic-]2) were determined at M = Ca, Sr, L ..... -

January 23, 2023 Research Article

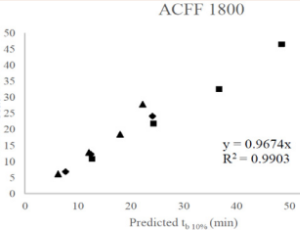

Abstract Activated Carbon Fiber (ACF) has properties that make it a great candidate as a sorbent in respirators against Volatile Organic Compounds (VOCs). Adsorption properties of ACF relevant for the determination of the potential service life, such as break.....

Abstract Activated Carbon Fiber (ACF) has properties that make it a great candidate as a sorbent in respirators against Volatile Organic Compounds (VOCs). Adsorption properties of ACF relevant for the determination of the potential service life, such as break..... -

February 27, 2023 Research Article

Abstract Background: Pine wilt disease (PWD) is a disease caused by the parasitization of Pinus spp. by Bursaphelenchus xylophilus, a pine wood nematode. This nematode is parasitic to insects and is thus transferred to the tree, growing in the tree for a shor.....

Abstract Background: Pine wilt disease (PWD) is a disease caused by the parasitization of Pinus spp. by Bursaphelenchus xylophilus, a pine wood nematode. This nematode is parasitic to insects and is thus transferred to the tree, growing in the tree for a shor..... -

February 27, 2023 Review Article

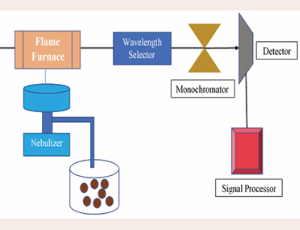

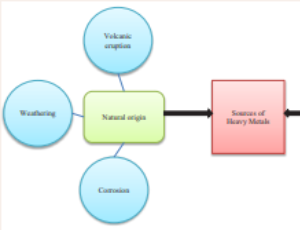

Abstract Environmental contamination by heavy metals is an issue of global health concern. With the incessant rise in various anthropogenic activities: the release of various organic and inorganic contaminants has continued to rise. Some of these activities i.....

Abstract Environmental contamination by heavy metals is an issue of global health concern. With the incessant rise in various anthropogenic activities: the release of various organic and inorganic contaminants has continued to rise. Some of these activities i.....