Contribution of the Marine Sediments of La-Goulette Harbor (Tunisia) in the Improvement of the RCC Compactness and Strength for Pavement

- 1. University of Tunis El Manar, National Engineering School of Tunis, Tunisia

- 2. University of Tunis - Higher National Engineering School of Tunis, Tunisia

- 3. Ecole Nationale Supérieure Mines-Télécom Lille-Douai, France

Abstract

The Roller Compacted Concrete (RCC) for pavement is presented as an evolutionary technology in which various types of aggregates are classically used, such as the crushed and the rolled either limestone or siliceous aggregates. The objective of the formulation methods of the RCC is the determination of optimal mixture of the different aggregates. The correct proportioning, of the cement and water, is also one of the important parameter to reach the maximum compactness.

The present work comported the study of the use of the marine sediments, in preparing RCC for pavement, as aggregates resulting from dredging of the La-Goulette harbor (Tunisia). This approach allows a profit from their contributions to the improvement of the mechanical strengths of the RCC. This study is based on the valorization of the marine sediments, classified as waste and where their storages remain harmful for the environment. Compressive Packing Model (CPM) was used for the formulation of the RCC mixtures. This study, containing also a mechanical characterization of the obtained material, showed that the marine sediments used, confer physically and economically considerable advantages to the RCC. The higher compactness and the mechanical strengths, obtained, showed the profitability of such RCC containing sediments.

KEYWORDS

- Roller Compacted Concrete (RCC)

- Marine Sediments

- Mechanical Characteristics

- CPM Model

CITATION

Zdiri M, Neji J, Ben Ouezdou M, Abriak N (2024) Contribution of the Marine Sediments of La-Goulette Harbor (Tunisia) in the Improvement of the RCC Compactness and Strength for Pavement. Ann Mar Biol Res 8(1): 1036.

ABBREVIATIONS

RCC: Roller Compacted Concrete; CC: Conventional Concretes; CPM: Compressible Packing Model; *ρ: Relative density (kg/ m3); LA: Los Angeles; MDE: Micro-Deval; FR: Flatting Ratio (%); LCPC: Laboratoire Central des Ponts et Chaussées (France); MPT: Maximum Paste Thickness; Fc: Compressive strength; Ft: Tensile strength.

INTRODUCTION

The Roller Compacted Concrete (RCC) behaves, in a fresh state, as a slightly wet soil because its slump test is equal zero [1]. The improvement of certain characteristics of the RCC mixtures, in fresh or hardened state, can obtained by the use of new, natural or artificial, materials and employed for the optimization of RCC characteristics. The formulation of the RCC mixture, containing the determination of the proportions, the granulometry of the aggregates and the water and cement dosage, should be studied at the laboratory in order to check the workability of the freshly- mixed concrete and to control the resistance of the hardened concrete [2].

In point of view granulometry, various types of materials were used, classically as aggregates, such as crashed and rolled limestone and siliceous aggregates [3]. In addition, the accumulation of sedimentary particles at the bottom of the harbors allows encumbering and blocking them. This slows down the flow, impeded the clear movement of boats and ships and prevents the transport activities that are practiced there. In order to maintain and to restore these accesses, it is necessary to achieve regularly operations of dredging and cleaning. Each operation comprises millions of tons (dry material) of marine sediments that are dredged in Tunisia. According to the characteristics of the sediments, valorization can interest several fields such as Civil engineering [4].

In the present work, marine sediments, resulting from the dredging of La-Goulette harbor, are introduced as an aggregate, in preparing RCC for pavement use. The marine sediments is used as aggregates for the contribution to the mechanical resistances and the improvement of the compactness of the mixtures of the RCC. To adopt this new approach, the following elements were treated while starting with the presentation and the characterization of the marine sediments and other granular materials used for the RCC manufacture. After that, the Compressible Packing Model of (CPM) was used for the formulation and the determination of the proportions of the components. Experimental tests of compression and tensile were carried out on cylindrical specimens, made by vibro-compaction according to the method of the French National project BaCaRa [5] and this for mixtures comprising marine sediments.

The used Materials and Granulometry distribution

In this study, carried out on the RCC technology and in particular on the various components of this material, the mixtures with the best performances are required. This study is adapted to the nature of materials available. It is focused on the identification of the components, the formulation and on compaction. In the formulation of the RCC mixtures, the best benefits from intrinsic qualities of material were required [6].

Binder: The high dosages of binders are not very profitable because a too high content of cement can inflate the production costs without increasing significantly the mechanical resistances or prolonging the lifespan of the coating. The used binder was a hydraulic Portland cement, which represents the permanent element of RCC manufacture. In this study, the used cement, C.E.M. II/C-L 32.5 had a relative density equal to 3038 kg/m3 [Table 1].

Table 1: Characteristics of hydraulic Portland cement.

|

Characteristics |

Values |

|

Beginning of cement setting (min) |

≥60 |

|

Expansion (mm) |

≤10 |

|

Initial strength (2 days) (Mpa) |

≥10 |

|

Final strength (28 days) (Mpa) |

≥32.5 |

|

Percentage of Sulphates (SO3) |

≤3.5% |

|

Percentage of Chlorates (Cl) |

≤0.1% |

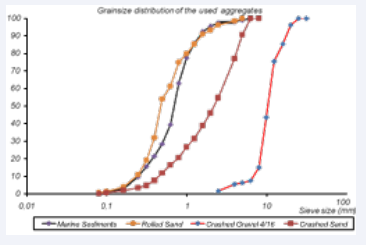

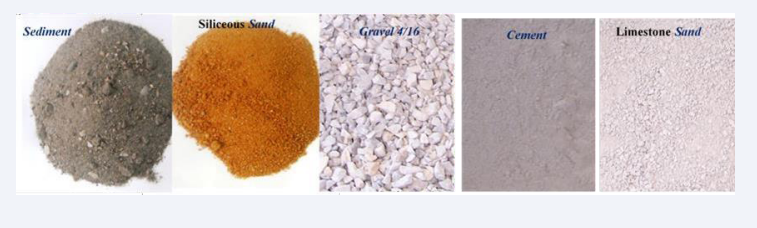

Aggregates: The aggregates represent an essential component and a permanent element of the RCC mixtures that conditions at the same time these characteristics and its cost. They constitute also the skeleton of this material and account for the 4/5 of the mixture weight [7]. Different classes of aggregates are necessary to fill the inter-aggregate space to the maximum. Two types of sand were used: rolled siliceous sand and crushed limestone sand. Crushed limestone gravel was also used. The characteristics and data relative to these aggregates are presented in [Table 2] and [Figure 1].

Table 2: Characteristics of aggregates

|

Aggregates |

Type |

Source |

kg/m3 |

MDE |

MDE % |

L.A |

|

Siliceous Sand |

Sand Rolled 0/5 |

Khlidia (1) |

2580 |

- |

- |

- |

|

limestone Sand |

Sand 0/4 |

Djebel Ouest 1 |

2530 |

- |

- |

- |

|

Marine Sediments |

Marine dredging |

harbor La-Goulette |

2472 |

- |

- |

- |

|

Gravel 4/16 |

Crashed Gravel |

Djebel El-Ressas 1 |

2690 |

19.54 |

18.38 |

27.65 |

Figure 1: Grain size distribution of the sediment and the used aggregates.

Marine Sediments: The granular fraction 0/5 plays an important role in the filling of inter-granular space and it improves

the compaction and consequently the mixture compactness. In this work, particular aggregates obtained by the dredging of La- Goulette harbor were useful as size range improving compactness of the RCC mixture. These sediments are fine particles of organic (humus) and inorganic (minerals) origins. The used marine sediments in this study are elements formed in the La-Goulette harbor in Tunis, the Tunisian capital [8].

The study of the chemical nature of the marine sediments proves that they will not cause later deteriorations for the RCC and that they are compatible with the used cements. The elementary chemical analysis and the characteristics of the sediments are presented in Table 3 and Figures 2&3.

Table 3: Characteristics of the marine sediments used.

|

Characteristics |

Marine Sediments |

|

Relative density (kg/m3) |

2472 |

|

Relative density after calcinations (kg/m3) |

2691 |

|

Content of organic matter at 450°C (%) |

9.45 |

|

Loss by fire after 12 h (%) |

14.75 |

Figure 2: Site of the La-Goulette harbor, source of the marine sediments.

Figure 3: Different used Materials: Sediment, cement and aggregates.

They comprise a majority of mineral particles lower than 63 μm of diameter and a content of organic matter from 2% to 12%.

Formulation through the CPM model

The objective of the formulation process of an RCC mixture is the optimization of the proportion of the dry components leading to obtain the higher characteristics. This optimization is in order to conform to certain requirements in spite of the low cement contents of these concretes (300 kg/m3).

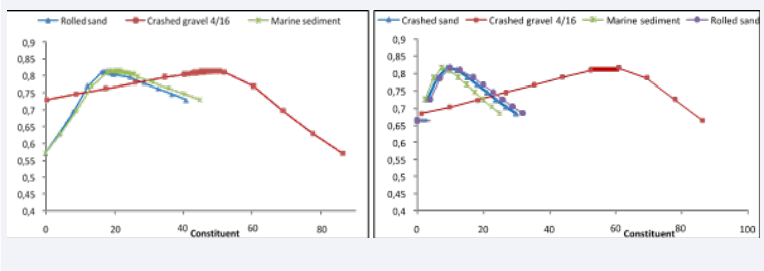

To obtain the percentages of the components, the Compressible Packing Model (CPM) [9] was applied through the software ‘Rene LCPC’, which was developed at Laboratoire Central des Ponts et Chaussées in France [10].

This model, designed for the formulation of conventional concretes (CC), was applied for the formulation of the RCC with optimal granular compactness.

The principle of this formulation method is based on the fact that the RCC mixture must generally conform to the used requirements. While based on the various proportions identified by the CPM model, six mixtures were obtained with different combinations of marine sediment, two types of sands and the crashed gravel [11]. The results from the model for the components of the six mixtures are presented in Tables 4 & 5 and Figure 4.

Table 4: Experimental Compactness’s of materials.

|

|

Dry Compactness |

Humid Compactness |

|

Cement CEM II |

0.540 |

- |

|

Rolled Sand |

0.642 |

0.444 at 4.6% |

|

Crashed Sand |

0.605 |

0.553 at 5.2% |

|

Marine Sediments |

0.651 |

0.710 at 7.6% |

|

Crashed Gravel 4/16 |

0.563 |

0.592 at 2.7% |

Table 5: Obtained percentages of the various components determined by CPM model.

|

|

M1 |

M2 |

M3 |

M4 |

M5 |

M6 |

|

Cement CEM II |

13.50 |

13.50 |

13.50 |

13.50 |

13.50 |

13.50 |

|

Rolled Sand |

26.90 |

- |

17.35 |

18.30 |

- |

12.40 |

|

Crashed Sand |

- |

27.20 |

- |

16.10 |

15.35 |

11.25 |

|

Marine Sediments |

- |

- |

19.50 |

- |

13.40 |

10.20 |

|

Crashed Gravel 4/16 |

59.60 |

59.30 |

49.65 |

52.10 |

57.75 |

52.65 |

|

Compactness |

0.8159 |

0.8042 |

0.8145 |

0.8025 |

0.8161 |

0.8110 |

Figure 4: Theoretical compactness and optimal proportions (%) by CPM Model.

Preparation of the mixtures and test set-up

While considering the proportions defined through the formulation methods by CPM model, 6 mixtures were studied (M1, M2, M3, M4, M5 and M6). The three mixtures (M1, M2 and M4), contained ordinary aggregates, the three others mixtures (M3, M5 and M6) were selected to contain proportions of marine sediments of La-Goulette harbor. The mixing of the various components of the mixtures was made in a concrete mixer. The parameter time of mixing is very important and it is strictly controlled. Mixing water is proportioned volumetrically.

To ensure an RCC of high quality, the basic components [Table 5] are suitably mixed in order to produce a homogeneous concrete where the entire aggregates surface is covered with cement paste. The specifications require that the RCC should be set up and compacted in the 60 mn that follows the beginning of mixing.

The specimens are made in the 30 minutes that follow mixing according to the automatic technique of compaction and according to the process of the National French project BaCaRa.

The specimens made for the strength control are of type: Cylindrical specimens with a diameter 160 mm and height 320 mm and permit to judge the mixture properties. The RCC was implemented into the mold in 3 layers each layers is compacted with a metallic rod, 25 strokes and then vibrated for 90 s under a load of 13 kg on a vibrating table [Figures 5].

Figure 5: Set-up and compaction of the specimens.

In a fresh state, the RCC contains in general, many vacuums. Its resistance is low and some settlements can occur under the action of the loads. To obtain a good “bearing pressure”, this material should be compacted. The goal of the compaction of the RCC is to obtain highest compactness. The objective is always to reach a compact configuration of the coarse aggregates.

RCC behavior in fresh state

In a fresh state, the workability is the principal property of the RCC. It represents the index of the effort that should be provided for well consolidating a fresh material. Since the RCC behaves like an intermediate material between a slightly wet soil and the concrete, its rheology can be characterized only by technological tests. The compactness of the RCC is thus employed for the evaluation of its rheological behavior in a fresh state.

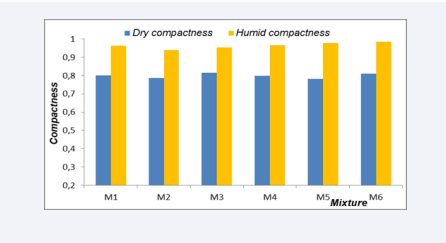

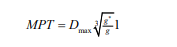

The determination of real compactness is made according to standard NF EN 1097-3. The experimental tests are carried out in cylindrical molds 16/32, under a pressure of 10 kPa, and vibrated during 1 mn with a vibrating table of frequency 50Hz. Measurements of compactness were made for the RCC mixtures in a dry and wet state. The results of experimental measurements are summarized on [Figure 6].

Figure 6: Experimental values of compactness for the RCC mixtures obtained in a dry and wet state.

MECHANICAL CHARACTERIZATION

The determination of the compressive strength of the RCC gives an overall indication of the quality of a concrete because it is linked directly to the hydrated cement paste structure and the kind of aggregates used. Moreover, the tensile strength represents an important element in designing an RCC pavement. Indeed, the optimization of the proportions of dry materials of the RCC mixtures lead to obtain high mechanical characteristics in spite of the low cement contents of these concretes.

After the setup of the specimens according to the process of the National French project BaCaRa. The specimens were released from the mold after 24 hours and were stored in water at a temperature of about 20° C and hygrometry more than 95%. Specimens 16/32 were tested in compression and in tensile by slitting by a tensile–compression machine of 3.106 N capacity at 3, 7, 14 and 28 days of age. The testing equipment is presented in [Figure 7] and a photograph of a cracked specimen is shown in [Figure 8].

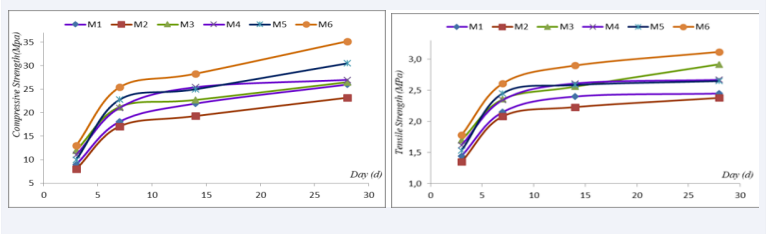

Figure 7: Variation of the compressive and tensile strengths versus time (for 6 mixtures).

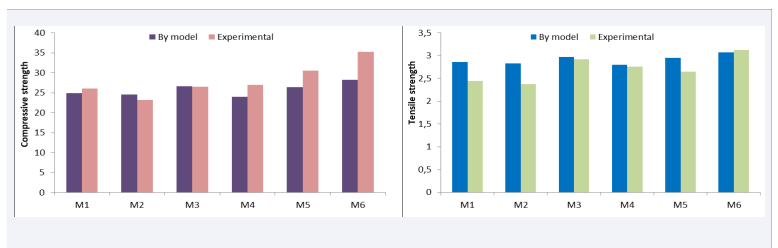

Figure 8: Compressive and Tensile strengths (by model and experimental).

The graphs present the plotted curves of variations of the compressive and tensile strengths according to the age of storage in water for the RCC specimens containing sediment or without sediments.

Examples of results are reported on [Figure 7] and which contain a superposition of the curves of variations of resistances for the 6 mixtures of RCC with and without sediments.

Interpretation

The study related to the analysis of the behavior and the evolution of resistance for the RCC mixtures containing the proportions of sediments that differ from the mixtures containing only the limestone’s and siliceous aggregates. The added sediments show also particular characteristics in granulometry and compositions.

- The compressive strengths of the RCC mixtures containing marine sediments of La- Goulette harbor M3, M5 and M6 were, clearly, higher than those of the RCC containing the classical aggregates (M1, M2 and M4).

- The M6 Mixture permit to reach compressive strength of 35.20 MPa and tensile strength by splitting of 3.12 MPa.

- The granular size of marine sediments of La-Goulette harbor has high compactness (0.651 in a dry state and 0.710 with water content equal to 7.6%). The addition of this material in the RCC formulation improves compactness of these mixtures and allows improving their resistances. This improvement is because the compressive and tensile strengths of the RCC mixtures require a high compactness of the granular skeleton and an optimal quantity of binder.

- In point of view rheology, the mechanical behavior of the RCC containing marine sediments of La-Goulette harbor is strongly influenced by the low volume of paste. It is noted, on the granular structure, that the compact skeleton of the RCC mixtures obtained contributes largely to the improvements of the mechanical performances.

- The addition of the marine sediments allows the reduction of porosity in the granular skeleton and by effect of densification, it allows the reduction of the demand in fine particles, such as cement.

PREDICTION OF THE COMPRESSIVE AND TENSILE STRENGTHS

To predict the compressive strength, the De Larrard and Tondat model was used by introducing the effect of the Maximum Paste Thickness (MPT) on the compressive strength.

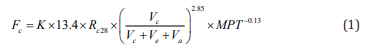

This prediction of the compressive strength was made by micro-buckling model. This model follows the power law and compressive strength is given by following equation 1:

Where Vc, Ve and Va are consecutively the cement, water and air volume, Rc28 is the cement characteristic resistance. K is a constant function of the aggregates used. For the case of the used aggregates, it is taken equal to 1.006.

The “MPT” represent the maximum distance between the two adjacent coarse aggregates seen in three dimensions. The following equation gives the “MPT”3:

Where Dmax is the maximal diameter of the largest aggregates and g is the volume of aggregate in a unit volume of concrete. g* is equal to the aggregate compactness assimilated to a granular mixture. It was measured or calculated with the CPM and presented in [Table 6].

Table 6: Characteristics of the RCC mixtures with and without sediment.

|

Mixtures Parameters |

M1 |

M2 |

M3 |

M4 |

M5 |

M6 |

|

Total weight of dry materials (kg) |

2234.91 |

2236.45 |

2224.16 |

2228.76 |

2234.25 |

2229.63 |

|

Water content w% |

6.3 |

6.3 |

6.4 |

6.2 |

6 |

6.5 |

|

Ve of water (l) |

140.80 |

140.90 |

142.35 |

138.18 |

134.06 |

144.93 |

|

Measured Compactness g |

0.709 |

0.709 |

0.708 |

0.712 |

0.716 |

0.705 |

|

Porosity |

0.185 |

0.2045 |

0.236 |

0.260 |

0.221 |

0.205 |

|

Calculated Compactness g* by CPM |

0.816 |

0.804 |

0.813 |

0.800 |

0.815 |

0.808 |

|

MPT (cm) |

0.768 |

0.683 |

0.760 |

0.638 |

0.708 |

0.748 |

|

Rc28 (MPa) |

32.5 |

32.5 |

32.5 |

32.5 |

32.5 |

32.5 |

|

Compressive strength Fc (MPa) |

24.972 |

24.439 |

26.695 |

24.089 |

26.745 |

28.088 |

|

Tensile strength Ft (MPa) |

2.863 |

2.828 |

2.974 |

2.805 |

2.977 |

3.062 |

To predict the tensile strength. The Rollet model was used. It is intended to predict from the compressive strength Fc. the tensile strength by splitting Ft of the RCC cylindrical specimen. This empiric model relates the two strengths by a power law expressed by the equation 3 [Table 6]:

strengths of the RCC is to evaluate the characteristics that will

involve cracking and the rupture.

- The adopted models in compression permit to obtain values that differ from 4.24 at 24.3% to those experimentally determined with an average difference of 14%.

- Through the adopted model for splitting tensile. The values of predictions differ from 1.5 at 19.05% to those in experimentally determined with an average difference of 10.25%.

- The resistance of the cementing matrix of the obtained mixture is strongly influenced by the compactness of the mixture. The low cement dosage of these mixtures produces a not very porous cementing matrix supporting suitable behavior and high resistances.

CONCLUSION

Through this study of RCC based on the marine sediments of La-Goulette harbor. The following conclusions were drawn:

- The compressive strength (>25 MPa) and the tensile strength (>3MPa), obtained by the RCC mixtures based on the marine sediments, are sufficient in order that the material can be implemented in base-courses or surfacing-courses of the roadways.

- This solution is presented as an alternative for the valorization of these sediments and to provide the economy through the reducing of the required quantities of ordinary aggregates.

- The high performance of the RCC, in compressive and tensile, is directly influenced by the compactness of the mixture. This compactness is improved by the addition of fines of marine sediments.

- The role of sediments fines in the RCC is thus to increase the compactness of the mixture. Indeed, the properties of the sediments offer to the RCC a high compactness giving a sufficient mechanical resistances and a pavement surface more closed.

- The high properties (compactness, resistances and densities) obtained through the use as of these aggregates in the RCC, explains the choice and reasons of the use of the marine sediments.

REFERENCES

- Gauthier P, Marchand J. Conception et réalisation de revêtements en béton compacté au rouleau au Québec, Association Béton de Québec (ABQ) Québec, Canada 2004.

- EUPAV European Concrete Paving Association. RCC: making concrete pavements available to the whole pavement building industry, Instituto del cemento y del hormigon. 2020.

- Zdiri M, Abriak N, Ben Ouezdou M, Neji J. The use of fluvial and marine sediments in the formulation of Roller Compacted Concrete for use in pavements. Environ Technol. 2009; 30: 809-815.

- Projet National BaCaRa (1988-1996) Le Béton Compacté au Rouleau, Presses ENPC, Paris. 3-79.

- Neville AM. Propriétés des bétons, Centre de recherche interuniversitaire sur le béton CRIB, Sherbrooke, Laval, Eyrolles France. 2000.

- ACPA’s, Roller-Compacted Concrete Task Force. Roller-Compacted Concrete Pavements as Exposed Wearing Surface. Instituto del cemento y del hormigon. 2018.

- Zdiri M, Ben Ouezdou M, Neji J. Theoretical and Experimental study of Roller Compacted Concrete strength. Magazine of Concrete Research. 2008; 60: 469-474.

- Thanh TN. Valorisation de sédiments marins et fluviaux en technique routière. 2009.

- Wang D. Solidification et valorisation des sédiments de port de dunkerque en travaux routières. 2011.

- De Larrard F. Concrete mixture proportioning -A scientific approach. 1999; 448.

- Pouliot N, Sedran T, De Larrard F, Marchand J. Prédiction de la compacité des bétons compactés au rouleau à l’aide d’un modèle d’empilement granulaire. Bulletin des Laboratoires des Ponts et Chaussées. 2001; 233: 23-36.

- Fakhri M, Saberi. F. The effect of waste rubber particles and silica fume on the mechanical properties of Roller Compacted Concrete Pavement. J Cleaner Production. 2016; 129: 521-530.

- Meddah A. Beddar M, Bali A. Use of shredded rubber tire aggregates for roller compacted concrete pavement. J Cleaner Production. 2014; 72: 187-192.