A Zero Liquid Discharge Desalination System Integrating Multi-Effect Distillation, Evaporative Crystallization, and Thermal Vapor Compression

- 1. Tsinghua Shenzhen International Graduate School, Tsinghua University, China

- 2. King Abdullah University of Science & Technology, Saudi Arabia

Abstract

TBrine is the by-product of desalination processes and contains most of the feed’s salts. Direct discharge of brine will cause severe issues for the environment. Therefore, designing zero liquid discharge desalination (ZLDD) systems has attracted extensive research interests. This paper presents a ZLDD system combining multi-effect distillation (MED), evaporative crystallization (EC), and thermal vapor compression (TVC). Seawater is concentrated to near saturation using two MED units and then salt is separated in the crystallizer. The vapor produced in the crystallizer is compressed to a higher pressure using the TVC, and the mixture of vapor and motive steam serves as the heat source for MED and EC. A thermodynamic analysis is firstly conducted on the proposed system. It takes 0.178 kg of high-pressure steam to desalinate 1 kg of seawater, and the pumping power consumption is 6.8 kJ/kg. Based on energy consumption, the cost of the system is calculated to be $3.51/m3 , with MED plant costs and thermal energy cost being the most important contributor.

Keywords

• Zero liquid discharge desalination

• Multi-effect distillation

• Evaporative crystallization

• Thermal vapor compression

CITATION

Chen Q, Ng KC (2023) A Zero Liquid Discharge Desalination System Integrating Multi-Effect Distillation, Evaporative Crystallization, and Thermal Vapor Compression. Chem Eng Process Tech 8(3): 1083.

INTRODUCTION

With growing global water consumption, desalination has become an important source of freshwater supply [1]. A new challenge brought up by the desalination industry is brine management. Most of the desalination plants can only separate a certain portion of freshwater from seawater [2-4]. The remaining stream is named the brine, and it contains most of the feed’s dissolved salts as well as pretreatment chemicals. Direct discharge of brine into the environment will cause negative impacts on the soil, water body, and aquarium ecosystems. With government legislation on brine discharge getting stricter, designing zero liquid discharge desalination (ZLDD) has gained much attention. ZLDD aims at completely separating seawater into freshwater and dry salts. It not only eliminates the need for brine discharge but also allows the recovery of valuable salts.

Several ZLDD systems have been reported in the literature. Most of them are based on conventional evaporative desalination processes and crystallization systems, such as membrane distillation crystallization (MDC) systems [5-9], multi-effect distillation/thermal vapor compression system (MED-TVC) [10], and mechanical vapor recompression (MVR) [11]. Most of them face the challenges of high energy intensity, high initial and operational costs, and high scaling and fouling issues.

This paper presents a novel ZLDD system consisting of two MED units and one evaporative crystallizer (EC). Seawater is firstly concentrated in the two MED units until its concentration approaches the solubility limit. Then the concentrated brine is supplied to the crystallizer for complete separation of water and salt. The vapor produced in the crystallizer is compressed to a higher pressure and temperature using a thermal vapor compressor (steam ejector), and the mixture of the vapor and the motive steam is used as the heat source of the three subsystems. Employment of the steam ejector not only simplifies the system design but also reduces heat consumption, which finally leads to a lower desalination cost.

SYSTEM DESCRIPTION

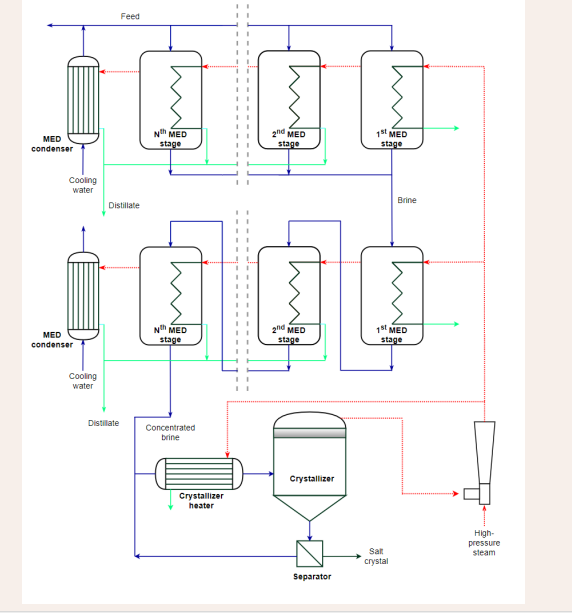

Figure 1 shows the schematic of the proposed zero liquid discharge desalination system.

Figure 1: Schematic of the proposed zero liquid discharge desalination (ZLDD) system integrating MED, EC, and TVC

It consists of two MED units, an evaporative crystallizer and a thermal vapor compression (jet ejector). The first MED has eight effects and employs parallel-feed configuration. It recovers ~50% of freshwater from seawater. The brine is directed to the second MED (forward-feed configuration, five effects) to be further concentrated to near saturation. The concentrated brine is finally fed to the evaporative crystallizer, where further evaporation is induced and brine reaches the super saturation state. As a result, salt precipitation takes place and crystals are formed. The vapor produced in the crystallizer is entrained into the ejector using high-pressure steam. The mixture of vapor and steam is discharged at moderate pressure and temperature, which constitutes the heat sources for the two MED units and the crystallizer.

METHODOLOGY

The performance of the proposed system is evaluated numerically. A thermodynamic analysis is firstly conducted by considering the heat and mass balances in each component.

Based on the calculated productivity and energy consumption, the specific cost for zero liquid discharge desalination is calculated by considering the initial and the operational and maintenance costs. The detailed model can be found in our previous publication [12].

RESULTS AND DISCUSSION

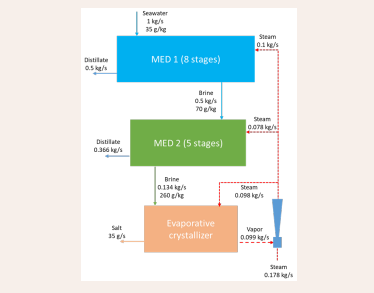

For demonstration purposes, the seawater flowrate is considered to be 1 kg/s and the salinity is 35 g/kg. Brine salinity leaving the first and the second MED units are designed to be 70 g/kg and 260 g/kg, respectively. Steam at 15 bar is employed as the heat source, and the discharge pressure and temperature for TVC are 75 ? and 38.6 kPa, respectively. Figure 2 shows the flow rates of different streams entering and leaving each subsystem.

Figure 2: Mass flow of different steams

Heating steam requirements in the two MED units and the crystallizer are 0.1, 0.078, and 0.098 kg/s, respectively, while vapor is produced in the crystallizer at 42.3 ?/8.3 kPa. The motive steam flowrate in the ejector is 0.178 kg/s, and the corresponding entrainment ratio of the ejector is 0.55.

Cooling water flow rates in the MED condensers are considered to be 10 kg/s. Pressure drops for MED feed, cooling water and crystallizer recirculation stream are 0.5, 2, and 1.5 bar, respectively, while pumping efficiency is 70%. Based on these assumptions, electricity consumption for pumping is estimated to be 6.8 kJ/kg.

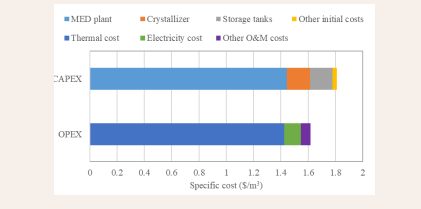

Employing the results of the thermodynamic simulation, the final cost is estimated. Table 1 summarizes the economic assumptions and the final desalination cost. Cost for MED plants and the ejector is adopted from [10], while crystallizer cost is acquired from [12]. The final cost is calculated to be $3.51 for treating per m3 of seawater.The cost breakdown is presented in Figure 3.

Table 1: Summary of economic analysis

|

Parameter |

Unit |

Value |

|

Seawater flowrate |

kg/s |

1 |

|

Seawater salinity |

g/kg |

35 |

|

Heat transfer area |

m2 |

321.16 |

|

Steam consumption |

kg/kgfeed |

0.18 |

|

Electricity consumption |

kJ/kgfeed |

6.8 |

|

Steam cost |

$/ton |

8.00 |

|

Electricity cost |

$/kWh |

0.065 |

|

Interest rate |

% |

5% |

|

Plant lifespan |

year |

30 |

|

Plant availability |

% |

90% |

|

Desalination cost |

$/m3 |

3.51 |

Figure 3: Cost breakdown of the proposed ZLDD system

The initial cost is around $1.8/m3, with MED plant cost being the largest contributor. The O&M cost is a bit lower than the initial cost (~$1.6/m3), and it is mostly contributed by the thermal energy cost. Further reduction of the cost can be achieved via designing cost-effective MED units, reducing heat consumption, and employing low-price heat sources.

CONCLUSIONS

A novel zero liquid discharge desalination (ZLDD) system consisting of multi-effect distillation (MED), evaporative crystallization (EC), and thermal vapor compression (TVC) has been evaluated. Thermodynamic analysis reveals that it takes 0.178 kg high-pressure steam to desalinate 1 kg of seawater, and the pumping power consumption is 6.8 kJ/kg. The life-cycle cost of the system is calculated to be $3.51/m3, which is mainly attributed to MED plant costs and steam cost. Cost reduction can be achieved via designing cost-effective MED units, reducing heat consumption, and employing low-price heat sources.

REFERENCES

- Virgili F, Pankratz T, Gasson J. IDA Desalination Yearbook 2015-2016.2016: Media Analytics Limited.

- Shahzad MW, Burhan M, Ng KC. Pushing desalination recovery to the maximum limit: Membrane and thermal processes integration.Desalination. 2017; 416: 54-64.

- Chen Q, Li Y, Chua K. On the thermodynamic analysis of a novel low- grade heat driven desalination system. Ener Conver Manag. 2016; 128: 145-159.

- Chen Q, Chua KJ. A spray assisted low-temperature desalination technology, in Emerging technologies for sustainable desalination handbook. Elsevier. 2018; 255-284.

- Lu KJ, Cheng ZL, Chang J, Luo L, Chung TS. Design of zero liquid discharge desalination (ZLDD) systems consisting of freeze desalination, membrane distillation, and crystallization powered by green energies. Desalination. 2019; 458: 66-75.

- Nakoa K, Rahaoui K, Date A, Akbarzadeh A. Sustainable zero liquid discharge desalination (SZLDD). Solar Energy. 2016; 135: 337-347.

- Guo H, Ali HM, Hassanzadeh A. Simulation study of flat-sheet air gap membrane distillation modules coupled with an evaporative crystallizer for zero liquid discharge water desalination. Appl Therm Engineer. 2016; 108: 486-501.

- Guan G, Wang R, Wicaksana F, Yang X, Fane AG. Analysis of membrane distillation crystallization system for high salinity brine treatment with zero discharge using Aspen flow sheet simulation. Indust Engineer Chem Res. 2012; 51: 13405-13413.

- Julian H, Meng S, Li H, Ye Y, Chen V. Effect of operation parameters on the mass transfer and fouling in submerged vacuum membrane distillation crystallization (VMDC) for inland brine water treatment. J Membra Sci. 2016; 520: 679-692.

- Panagopoulos A. Process simulation and techno-economic assessment of a zero liquid discharge/multi-effect desalination/ thermal vapor compression (ZLD/MED/TVC) system. Int J Ener Res. 2020; 44: 473-495.

- Onishi VC, Carrero-Parreno A, Reyes-Labarta JA, Fraga ES, Caballero JA. Desalination of shale gas produced water: A rigorous design approach for zero-liquid discharge evaporation systems. J Clean Produ. 2017; 140: 1399-1414.

- Chen Q, Burhan M, Shahzad MW, Ybyraiymkul D, Akhtar FH, Li Y, et al. A zero liquid discharge system integrating multi-effect distillation and evaporative crystallization for desalination brine treatment. Desalination. 2021; 502: 114928.