Co-Digestion of Glycerol with Municipal Wastewater

- 1. Hawaii Natural Energy Institute, University of Hawaii at Manoa, USA

- 2. RealGreen Power, Honolulu, USA

ABSTRACT

The production of biodiesel, an environmentally friendly alternative to fossil based fuel sources, is creating a surplus of crude glycerol (CG). As CG is a highly regulated waste stream, new and effective methodologies to process CG into useful products are needed to cover the costs associated with its disposal. In this paper we present the results of a study that used a demonstration-scale low-energy high-rate anaerobic aerobic digestion (HRAAD) system to evaluate the potential of co-digesting CG with sewage wastewater (primary clarifier effluent, PCE). The HRAAD system consisted of an initial anaerobic packed bed (AnPB) reactor fed a PCE-glycerol mixture possessing a chemical oxygen demand (COD) of 3.07 g l-1 at a hydraulic residence time (HRT) of 2 days (organic loading rate (OLR) of 1.53 kg m-3 d-1) and achieved a COD reduction of approximately 65%. The biogas produced possessed 65% methane (CH4 ) at a yield of 0.20 m3 CH4 per kg CODred at standard temperature and pressure (STP). The effluent from the AnPB (COD: 1.083 g l-1, OLR: 1.28 kg COD m-3 d-1) was fed to the second downstream aerobic trickling filter (TF) reactor that produced an effluent COD of 0.809 g l-1 achieving an overall HRAAD system COD reduction of 74% (i.e. across both AnPB and TF reactors). Ammonia reduction across the AnPB reactor was 68% with a total system reduction of 91%. Nitrites and nitrates in both reactor effluents were completely absent. In total, these results support that the co-digestion of high strength acidic CG (COD: ~1.5 kg l-1 and pH: 4) with sewage wastewater is an attractive solution to process excess CG.

KEYWORDS

• High rate anaerobic aerobic digestion

• Biodiesel waste

• Crude glycerol

• Environmental cost

• Sewage

• Biogas

CITATION

Lamichhane KM, Furukawa D, Cooney MJ (2017) Co-Digestion of Glycerol with Municipal Wastewater. Chem Eng Process Tech 3(1): 1034.

ABBREVIATIONS

HRAAD: High Rate Anaerobic Aerobic Digestion; CG: Crude Glycerol; PCE: Primary Clarifier Effluent; WW: Wastewater; AnPB: Anaerobic Packed Bed; TF: Trickling Filter; ST: Settling Tank; MT: Mixing Tank; HRT: Hydraulic Residence Time; OLR: Organic Loading Rate; COD: Chemical Oxygen Demand; TN: Total Nitrogen; TP: Total Phosphorus; TSS: Total Suspended Solids; WWTP: Wastewater Treatment Plant, CODred: Chemical Oxygen Demand reduced; STP: Standard Temperature And Pressure; cft: cubic feet.

INTRODUCTION

Biodiesel has emerged as an important renewable fuel source, especially because it can be blended with petroleum based fuels [1]. Advantages to biodiesel blending include increased fuel lubricity and the utilization of waste products (i.e. recycled restaurant grease). Biodiesel production, however, produces crude glycerol (CG), a waste product that suffers strict regulatory discharge requirements because of its high organic strength, extreme pH, high viscosity, and impurities such as ash, soap, heavy metals, inorganic salts, and methanol [2,3]. The presence of methanol in CG can also make it ignitable and corrosive [4]. Currently, annual global demand for glycerol for the manufacture of drugs, food, paints, tooth paste, cosmetics etc is 1.81 million tons relative to an annual global production of 1.78 million tons from the conventional production routes [5]. Biodiesel production, however, is expected to boost (crude) glycerol production to estimated 17.6 million tons in the year 2016 [6]. Given these numbers, biodiesel production is expected to create a glycerol glut in the market [7]. As such, the biodiesel industry must find new ways to dispose of CG that are cost effective and pose minimal impact upon the environment.

Though multiple pathways currently exist to dispose or process CG, each has its limitations. Impurities such as methanol, free fatty acids, heavy metals, inorganic salts, methyl esters, water, soap, oil, and ashes present in CG make it difficult to recycle and reuse [2,8,9]. Classic bioconversion methods such as codigestion with sewage sludge cannot process glycerol at the pace of its production, co-composting with food and other wastes require specialized operational measures and is highly regulated [10], high purity processes are far too costly for small and medium-sized industries [9], and anaerobic co-digestion with sewage sludge requires long residence times (20-40 d) and suffers process instability and poor digestate dewaterability [11]. Finally, direct combustion requires expensive processes to remove water and impurities before use [8]. New methods to treat CG should, therefore, be investigated.

Although there are a few studies that have evaluated the codigestion of CG with industrial wastewater (WW) [12-14], there are no known reports on its co-digestion with sewage WW. Given that the known suite of disposal pathways are expensive and/or problematic, and the fact that the amount of sewage WW flowing through WWTPs is much larger than the amount of sewage sludge, the co-digestion of crude glycerol with sewage WW is potentially an attractive alternative. In this study we present the results of a demonstration-scale study that has evaluated the codigestion of CG with sewage WW including its potential for biogas production.

MATERIALS AND METHODS

The experimental setup

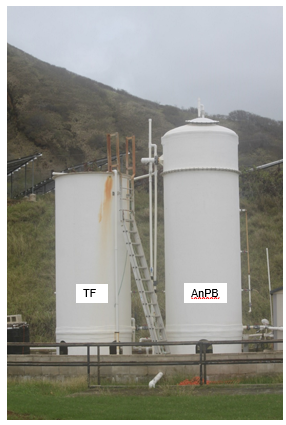

The evaluation was executed using a demonstration-scale high-rate anaerobic aerobic digester (HRAAD) system installed on the premises of Hawaii American Water East Honolulu Wastewater Treatment Plant (HAWWTP). The system consisted of two 3,000 gallon (~11.35 m3 ) fiber glass towers connected in series (Figure 1).

Figure 1: Pilot test plant installed at East Honolulu Wastewater Treatment Plant’s (EHWWTP) premises in Honolulu. The tower on the right is anaerobic packed bed (AnPB) reactor operated in upflow mode and the column to the left is a trickling filter.

Operated in an upflow mode, the first anaerobic packed bed (AnPB) reactor was packed with a mixture of biochar and thin fibrous ribbons of premade rubber and PVC while the second downflow aerobic trickling filter (TF) was packed with high surface area PVC media (Jaeger, Bio-Pac SF#30). The working volume of AnPB and TF reactors were 9.46 m3 and 4 m3 , respectively. The effluent from the AnPB reactor flowed to the TF whose effluent then flowed to a settling tank (ST) by gravity. Internal recycle (2x) was applied to both the AnPB and TF reactors. CG was collected in bulk from Pacific Biodiesel, a local company that produces CG from its biodiesel production process. Separate pumps, pumping both PCE and CG, were run once every two hours for 20 minutes to achieve flow rates of 46.5 ml min1 (11.18 l d-1) and 19.71 l min-1 (4,731 l d-1), respectively into a single pre-mixing tank (MT). The feed (CG and PCE mixture) was then pumped into the AnPB reactor at a rate needed to achieve a hydraulic residence time (HRT) of 2 days in the anaerobic (AnPB) reactor. The HRT is a key processing parameter defining the system performance as it determines the contact time of the crude glycerol with microbiota in the system reactors. The HRAAD reactor system had previously been used for studies related to wastewater treatment [15] and was therefore acclimated to sewage WW over two year period at varying HRTs. To acclimate and establish baseline steady state operation prior with respect to the co-digestion of the CG, the system was continuously run with sewage WW for two weeks at a HRT of 7.5 h. The performance of the HRAAD system in co-digesting CG with PCE was then monitored for one and half months.

Sample collection and analysis

Liquid phase samples from AnPB and TF reactors were collected from designated ports on effluent lines while samples from the MT were collected viaa top sampling port. Collected samples were stored on ice and transported to the lab where they were immediately analyzed for chemical oxygen demand (COD), total nitrogen (TN), total phosphorus (TP), and total suspended solids (TSS) -all using Standard Methods [16]. pH was measured using an industrial pH meter (Omega, industrial electrode PHE7151). Both temperature and pH were measured on-site three times a week. Volatile organic acids (VOAs) were detected by HPLC (Agilent Technologies, Biorad Aminex HPX-87H column) using established methods [17]. Ions were quantified using ion chromatography (dual Dionex ICS-1100s, Thermo Scientific) with conductivity detectors. Filtered samples were used for both VOAs (0.2 µm pore) and ions (1.5 µm pore) detection. The biogas production rate was measured on a cumulative basis using a gas meter (BK-G4, Elster International). Biogas samples were collected in 500 ml-Tedlar Bags (Zefon International) and analyzed for composition by GC as per protocols previously reported [17].

The COD, BOD5 , TN, TP, TSS, and pH of the PCE fluctuated in the range 238-303 mg l-1, 61.8-88.9 mg l-1, 31-59 mg l-1, 12-13 mg l -1, 31-67 mg l-1, and 7.13-7.56, respectively. The mean COD, TN, TP, TSS, and pH of the CG were 1,471 g l-1, 0.765 g l-1, 0.385 g l -1, 0.612 g l-1, and 4.0, respectively. The CG also contained heavy metals arsenic, cadmium, cobalt, chromium, copper, nickel, lead, selenium, and zinc all at low concentrations (< 1 µg l-1) (data not shown). When combined, the PCE and the CG yielded a feed which possessed a mean COD of 3.07 g l-1 and loaded into the AnPB reactor at an organic loading rate (OLR) of 1.53 kg m-3 d-1. The mean TN, TP, and TSS concentrations of the feed were 39.1 mg l -1, 18.6 mg l-1, and 50.7 mg l-1, respectively. The concentrations of VOAs, ions, and other compounds present in the CG, and in the feed (CG and PCE mixture) are given in (Table 1).

Table 1: Steady state concentrations of various parameters (organics, nutrients, VOAs, anions, and cations) in liquid phase samples.

|

Particulars |

Concentrations |

|

Reduction across (%) |

|||||

|

PCE |

CG |

Feed (PCE+CG mixture) |

AnPB effluent |

TF effluent |

AnPB |

TF |

||

|

Organics and nutrients |

|

|

|

|

|

|

|

|

|

COD (g l-1) |

0.271 |

1,471 |

3.07 |

1.08 |

0.81 |

64.7 |

73.7 |

|

|

TN (mg l-1) |

45 |

765 |

39.1 |

31.8 |

31.3 |

18.7 |

19.9 |

|

|

TP (mg l-1) |

12.5 |

385 |

18.6 |

10.6 |

10.7 |

43 |

43 |

|

|

TSS (mg l-1) |

49 |

612 |

50.7 |

42.7 |

42.5 |

15.8 |

16.2 |

|

|

VOAs |

|

|

|

|

|

|

|

|

|

Glucose (g l-1) |

BDL |

3.76 |

BDL |

BDL |

BDL |

100 |

100 |

|

|

Glycerol (g l-1) |

BDL |

1260 |

1.92 |

BDL |

BDL |

100 |

100 |

|

|

Acetate (g l-1) |

0.01 |

3.99 |

0.042 |

0.053 |

0.036 |

+ |

14.3 |

|

|

Acetoin (g l-1) |

BDL |

3.53 |

0.184 |

0.395 |

0.149 |

+ |

19.0 |

|

|

Butyrate (g l-1) |

BDL |

BDL |

0.011 |

0.0275 |

0.011 |

+ |

0 |

|

|

Ethanol (g l-1) |

BDL |

4.99 |

BDL |

BDL |

BDL |

|

|

|

|

Butyraldehyde (g l-1) |

BDL |

BDL |

0.02 |

0.0425 |

BDL |

+ |

100 |

|

|

IONs |

|

|

|

|

|

|

|

|

|

Chloride (g l-1) |

1.377 |

5.15 |

2.96 |

2.44 |

2.6 |

17.6 |

12.2 |

|

|

Bromide (g l-1) |

0.008 |

39.8 |

0.104 |

0.013 |

0.011 |

87.5 |

89.4 |

|

|

Nitrite (g l-1) |

BDL |

BDL |

BDL |

BDL |

BDL |

|

|

|

|

Nitrate (g l-1) |

BDL |

BDL |

BDL |

BDL |

BDL |

|

|

|

|

Phosphate (g l-1) |

BDL |

BDL |

BDL |

BDL |

BDL |

|

|

|

|

Sulfate (g l-1) |

0.388 |

1.5 |

0.394 |

0.004 |

0.222 |

99 |

43.6 |

|

|

Sodium (g l-1) |

1377 |

1.25 |

1.61 |

1.34 |

1.36 |

15.5 |

15.5 |

|

|

Ammonium (g l-1) |

0.026 |

0.385 |

0.028 |

0.0089 |

0.0009 |

67.9 |

90.9 |

|

|

Potassium (g l-1) |

0.055 |

27.51 |

0.132 |

0.086 |

0.081 |

34.8 |

38.6 |

|

|

Magnesium (g l-1) |

0.237 |

0.01 |

0.262 |

0.238 |

0.207 |

9.2 |

21 |

|

|

Calcium (g l-1) |

0.114 |

0.03 |

0.123 |

0.126 |

0.108 |

+ |

12.2 |

|

Abbreviations: VOA: Volatile Organic Acids; CG: Crude Glycerol; PCE: Primary Clarified Effluent; AnPB- Anaerobic Packed Bed; TF: Trickling Filter; BDL: Below Detection Limit (or not detected); g l-1: gram per liter; mg l-1: milligram per liter; + signifies concentration increase.

RESULTS AND DISCUSSION

Results

The HRAAD system demonstrated stable performance over the entire period of operation in terms of consistent pollutants reduction (for e.g., COD), biogas production, and stability in reactor pH. The AnPB reactor produced an effluent possessing an average COD of 1.083 g l-1, achieving a COD reduction of approximately 65%. All VOAs and intermediate products except acetate, butyrate, and butyraldehyde were completely removed from the AnPB effluent (Table 1). The effluent from the AnPB (COD: 1.083 g l-1) was loaded into the TF at an OLR of 1.28 kg COD m-3 d-1. The average COD of the TF effluent was 0.809 g l-1 yielding a total HRAAD system (AnPB and TF combined) COD reduction of approximately 74%. The mean pH of the AnPB and TF effluents were 6.66, and 7.39, respectively. Butyraldehyde completely disappeared from the TF effluent although acetate was still present at reduced concentrations. The ions nitrites and nitrates were completely absent in both AnPB and TF effluents. The daily biogas production approached 100 cubic feet (cft) (~2,832 l) after one month of operation and remained relatively constant over a narrow range (90-113 cft d-1) till the end of the experiment (i.e. day- 45). The maximum biogas production rate realized was 3,199.8 l d-1 with an average composition of 64.48% methane (CH4 ), yielding maximum CH4 production of 2,063 l d-1 equivalent to 1,876 l d-1 at standard temperature and pressure (STP). At this rate, the CH4 yield was approximately 0.20 m3 CH4 per kg COD degraded, a value comparable to the theoretical maximum of 0.35 m3 CH4 per kg COD degraded. Table (1) summarizes steady state performance of the system.

Discussion

The stable performance of the AnPB (and the HRAAD) system over the experimental period suggests high potential for codigestion of CG with sewage WW. A complete absence of nitrites and nitrates in both AnPB and TF effluents coupled with a sharp decrease in ammonium concentration across the HRAAD system (26 mg l-1 in PCE, 9 mg l-1 in AnPB effluent, and 0.89 mg l-1 in the TF effluent) indicated that co-digestion of PCE with glycerol is a good way to remove excess nutrients in sewage WW that are not otherwise removed by traditional aerated WW treatment methods. In other words, the carbon provided by the CG in the water balances the nutrients (nitrogen) in the sewage WW. These results are useful because effluents with such low in N (i.e. ammonia, nitrite, and nitrate) do not need additional nitrification and denitrification processing.

Although, co-digestion of CG with sewage sludge is a heavily reported CG management alternative, the potential advantages of co-digestion of CG with sewage WW over sewage sludge, however, are numerous. First, HRAAD systems can be installed in between existing primary clarifier and secondary activated sludge unit operations, offering both ease of integration into WWTP’s as well as useful addition points for the CG. In this manner, the CG addition to the system can be easily controlled, modulated, and adjusted to address diurnal loading variations to the sewage WW flow. Second, it improves biogas production as well reducing organics (and also nutrients), thus, economizing subsequent treatment processes such as nitrification and denitrification in WWTPs. Third, this process avoids the problems of mixing, blockage, and inhibition of nutrients diffusion that commonly occur with the co-digestion of CG with sewage sludge. Codigestion with sewage WW (HRT: 2 d) will also process CG much faster than co-digesting with sludge (HRT: 20-40 d).Finally, the treated effluent can be discharged back to the existing activated sludge line necessitating no new discharge permits.

CONCLUSION

The HRAAD system utilized in this study is a robust process that provides stable performance and achieves good COD reduction rates (74%) and methane yields (0.20 m3 CH4 per kg CODred). The co-digestion of CG with sewage wastewater, thus, can be a useful low-energy low-nutrients treatment alternative to CG management. The co-digestion process utilizes the excess nutrients in the sewage WW to biologically degrade the carbon in the CG, thus, negating the need for the addition of nutrients to digest the carbon in the CG. Small communities with WWTPs can provide local biodiesel producers the opportunity for low cost CG treatment with additional recovery of biogas. More, as no chemicals are used in the process, the system does not produce any additional byproducts that attract disposal requirements.

ACKNOWLEDGEMENTS

Authors would like to acknowledge Office of Naval Research (Grant no.: N00014-16-1-2116) for sponsoring the research, Pacific Biodiesel for volunteering crude glycerol, Hawaii American Water for giving the access and the space for pilot plant installation, and Ms. Kexin Rong for her help in laboratory analysis.

REFERENCES

- AFDC. Diesel Vehicles Using Biodiesel. 2016.

- Thompson JC, He BB. Characterization of Crude Glycerol from Biodiesel Production from Multiple Feedstocks. Applied Engineering in Agriculture. 2006; 22: 261-265.

- Chatzifragkou A, Papanikolaou S. Effect of impurities in biodiesel-derived waste glycerol on the performance and feasibility of biotechnological processes. Appl Microbiol Biotechnol. 2012; 95: 13-27.

- EPA. Biofuels, Non-commercial and Home Biodiesel Waste. Reduce, Recycle, and Reuse. 2016.

- Khanna S, Goyal A, Moholkar VS. Microbial conversion of glycerol: present status and future prospects. Crit Rev Biotechnol. 2012; 32: 235.

- Anand P, Saxena RK. A comparative study of solvent-assisted pretreatment of biodiesel derived crude glycerol on growth and 1,3-propanediol production from Citrobacter freundii. N Biotechnol. 2012; 29: 199-205.

- Fangxia Yang, Milford A. Hanna, Runcang Sun. Value-added uses for crude glycerol--a byproduct of biodiesel production. Biotechnology for Biofuels. 2012; 5: 13.

- Johnson DT, Taconi KA. The glycerin glut: Options for the value?added conversion of crude glycerol resulting from biodiesel production. Environmental Progress. 2007; 26: 338-348.

- Pagliaro M, Rossi M. Glycerol: Properties and Production, in the Future of Glycerol (2), Pagliaro M, Rossi M. Editors. The Royal Society of Chemistry: London, UK. 2010; 1-28.

- EPA, Environmental Laws Applicable to Construction and Operation of Biodiesel Production Facilities. U.S. Environmental Protection Agency Region 7: USA. 2008.

- Silvestre G, Fernández B, Bonmatí A. Addition of crude glycerine as strategy to balance the C/N ratio on sewage sludge thermophilic and mesophilic anaerobic co-digestion. Bioresour Technol. 2015; 193: 377-385.

- Lucas Jose Foucault. Anaerobic Co-digestion of Chicken Processing Wastewater and Crude Glycerol from Biodiesel, in Biological and Agricultural Engineering. Texas A&M University: Texas. 2011; 96.

- Ma J, Van Wambeke M, Carballa M, Verstraete W. Improvement of the anaerobic treatment of potato processing wastewater in a UASB reactor by co-digestion with glycerol. Biotechnol Lett. 2008; 30: 861-867.

- Panpong K, Srisuwan G, O-Thong S, Kongjan P. Anaerobic Co-digestion of Canned Seafood Wastewater with Glycerol Waste for Enhanced Biogas Production. Energy Procedia. 2014; 52: 328-336.

- Postacchini L, Lamichhane KM, Furukawa D, Babcock RW Jr, Ciarapica FE, Cooney MJ. Life cycle assessment comparison of activated sludge, trickling filter, and high-rate anaerobic-aerobic digestion (HRAAD). Water Sci Technol. 2016. 73: 2353-2360.

- Lopez RJ, Higgins SR, Pagaling E, Yan T, Cooney MJ. High rate anaerobic digestion of wastewater separated from grease trap waste. Renewable Energy. 2014; 62: 234-242.

- Cooney M, Maynard N, Cannizzaro C, Benemann J. Two-phase anaerobic digestion for production of hydrogen–methane mixtures. Bioresour Technol. 2007; 98: 2641-2651.