Effluent Characterization and Waterbody Monitoring From an Olive Pomace Oil Extractor Industry

- 1. Department of Chemical and Biological Technology, Polytechnic Institute of Bragança, Portugal

- 2. Department of Chemical Engineering, Universidade Tecnológica Federal do Paraná (UTFPR), Brazil

ABSTRACT

The environmental impact is a relevant aspect of the production of Olive oil, the residues, olive mill wastewater (OMWW), and olive pomace, became one important focus to the circular economy, one of the many valorizations economically viable is olive pomace oil. The olive pomace oil industry is responsible for a secondary oil extraction based on mixing organic solvent with the olive pomace. This process produces a wastewater what was physicochemical characterized- COD, BOD, TS, TSS, FOG, organic nitrogen, ammonia and phosphorus content, pH and conductivity, phenolic compounds, and aromaticity, and Zahn-Wellens biodegradation test- in this study as the first step to a wastewater design for the factory. The main objective is to be able to return the treated wastewater in the river next to the factory with the required quality by the Portuguese legislation. The river water was also characterized in four different points to evaluate the factory environmental impact. The results show no large variation in the analyzed parameters when compared with the current legislation.

KEYWORDS

• Industrial effluent

• Wastewater characterization

• Olive pomace oil

• Industrial effluent

• Characterization

• Treatment

CITATION

MAZUR A, de A PIETROBELLI JMT, MARTINS RJE (2022) Effluent Characterization and Waterbody Monitoring From an Olive Pomace Oil Extractor Industry. Chem Eng Process Tech 7(2): 1067.

INTRODUCTION

Olive oil production is a relevant Portuguese economic sector, with job creation, maintaining rural populations; its production involves also environmental aspects that cannot be neglected [1]. Mass and energy resources are consumed throughout the stages of the olive oil production chain, from the cultivation and production of olives to the final consumption of the product, as well as produced gaseous, liquid, and solid residues with impacts on ecosystems [2]. Utilizing the circular economy approach, these residues can still be part of new industrial processes before receiving treatment and final disposal, as it happens in the production of the olive pomace oil.

Olive oil is a vegetable oil that only needs mechanical processes to be extracted and can be considered the juice from olives. First, the olive needs some pre-treatments such as removal of leaves and stones, separation, conservation, cleaning, and washing to guarantee a good quality of the final product [1]. Then the olives are milled in a process called malaxation with a hammer or toothed-disc crushers and thermal bathing producing an olive paste. Using a liquid-solid separation process, the olive oil is separated from the olive pomace, producing as by-product, the OMWW [3,4].

The technologies for olive oil extraction became more efficient over the decades, today most extraction occurs in a 2-phases system to reduce the amount of wastewater produced by the traditional and the 3-phase process. Nonetheless, the production of olive pomace is 3 to 5 times bigger than the olive oil [1], evidencing the importance of the olive pomace oil industry even though the bagasse has around 8-10% olive oil remaining [4].

The main by-product, the olive pomace, goes to a second extraction, the remaining oil percentage is removed applying an organic solvent, and this olive pomace oil can be refined and used in some countries in the food and cosmetic industries and biodiesel production. After the process, the exhausted pomace serves as fuel in the industry, and the wastewaters produced need to be treated to give a destination to water and organics compounds [5].

Wastewater treatment design bins in the characterization of liquid outlet of industrial plant, identifying the pollutant composts present, estimate the volumes and the source of generation, in some cases a corrective action can be proposed to reduce or even eliminate the pollutant levels. This knowledge is also important to evaluate which of the next steps in wastewater treatments are required, comparing the data to the specifications requested on the final effluent, obtained in the local legislation or equipment/ process demands [6,7].

The overall aim of this work is to study the effluent from an olive pomace oil extractor industry promoting its physiochemical characterization and access the water quality of the local river, based on the established parameters by Portuguese Environmental Legislation. Witch the data obtain in this work a wastewater treatment can be design in the future and the impact caused by the final disposal of the wastewater can be monitored in the water body.

MATERIAL AND METHODS

The wastewater used in this study was collected on Mirabaga, an olive pomace oil extractor industry, in Mirandela (Portugal), between April and May 2021. The amount of wastewater was delivered to the laboratory and stored as required by the Standard Methods for the Examination of Water and Wastewater, (2005), for the analysis and tests. This study was carried out at the Chemical Process Laboratory, at the Polytechnic Institute de Braganza (IPB), Portugal.

Wastewater characterization

Applying the Standard Methods for the Examination of Water and Wastewater [8], the parameters choose to be determined were pH and conductivity, Biochemical Oxygen Demand (BOD5), Chemical Oxygen Demand (COD), total phosphorus content, ammonia and organic nitrogen content, Fats, Oils and Grease (FOG), aromaticity, phenolic compounds, alkalinity, and Total Solids (TS) and Total Suspended Solids (TSS). Zahn-Wellens Biodegradation tests were conducted as the OECD guideline for testing of chemicals (1992) [9].

Water characterization

Applying the Standard Methods for the Examination of Water and Wastewater [8], the parameters choose to be determined were temperature, conductivity, dissolved oxygen and total dissolved solids were measured in situ, pH and turbidity, Biochemical Oxygen Demand (BOD5), Chemical Oxygen Demand (COD), total phosphorus content, ammonia and organic nitrogen and nitrate content, oils and grease, aromaticity, phenolic compounds, alkalinity and Total Solids (TS), Total Suspended Solids (TSS) and Total Dissolved Solids (TDS).

OLIVE POMACE OIL EXTRACTOR INDUSTRY

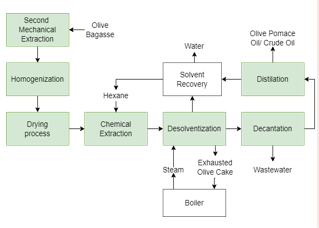

According to the traditional method of solvent extraction, the olive pomace needs to be dried to 8% moisture before the addition of an organic solvent, although it reflects a minor part of the olive pomace sold to the second extraction industry [8]. In deterrence the high percentage of water in olive pomace oil, some extraction facilities who receive the three types of olive bagasse have chosen to homogenize the moisture content of the pomace to be extracted as shown in Figure 1,

Figure 1: Olive Pomace Oil production process.

mixing the three types of bagasse until they reach a humidity of around 50% before a drying process. This process is important to stop fermentation reactions and preserve the reminiscent oil from hydrolysis and enzymatic deterioration [4].

After drying, the olive pomace is mixed with a solvent for the extraction of fats. This solvent needs to have no influence on the oil quality and physical properties, also a good selectivity and extraction power. As for other vegetable oils, the most commonly used is n-Hexane [6].

The solvent/oil mixture is collected from the batch extractors and steam is injected in a desolventizer operation to eliminate the hexane residue from the solids, and the oil/hexane mixture will be distilled to recover solvent [3]. The olive pomace oil obtained, also called crude pomace oil, differs from the virgin olive oil, it is more acidic, has a dark green coloration due to its high chlorophyll content and unpleasant odor and taste, needing a refining procedure to become edible [10].

The residues generated are biomass composed of stones and fat-free solids (or exhausted olive cake), and residual wastewater. The exhausted olive pomace can have the pulp separated from the rest and destined to animal feed, the residue remaining is used as a fuel, reducing the fuel demand for steam production of the installation [6,11].

WASTEWATER CHARACTERIZATION

Vegetable oil-producing industries are an important food industry, and as many have wastewater with specific characteristics, like color, odor, high BOD and COD, FOG is also the main pollutant in the wastewaters of the olive oil industry [7].

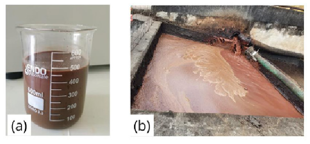

The wastewater was collected from two different locals in the factory. The first is collected in the wastewater exit from the industrial process- the place and aspect can be seen in Figure 2(a), and 2(b).

Figure 2ab: Industrial effluents and effluents collection sites.

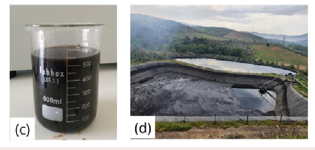

The second is from the second pool where the effluent is stored, the place and aspect are shown in Figure 2(c), and 2(d).

Figure 2cd: Industrial effluents and effluents collection sites.

The visual aspect of the two wastewater is very distinct in color and turbidity. Effluent 1 is new, has a higher amount of BOD and suspended solids, as shown in Table 1,

Table 1: Olive pomace oil wastewater characterization.

|

Parameter |

Unit |

Effluent |

|

|

1 |

2 |

||

|

pH |

- |

4.21 |

4.97 |

|

Conductivity |

mS/cm |

9.30 |

8.80 |

|

BOD5 |

g O2/L |

48.40 |

15.01 |

|

COD |

g O2/L |

126.64 |

28.52 |

|

Organic Nitrogen |

g N/L |

1.48 |

0.21 |

|

Ammoniacal Nitrogen |

mg N/L |

73.13 |

19.87 |

|

Total Phosphorus |

g P/L |

0.54 |

0.33 |

|

FOG |

g/L |

4.62 |

2.63 |

|

Phenolic compounds |

g/L |

7.82 |

1.42 |

|

Aromaticity |

g/L |

51.66 |

11.74 |

|

Alkalinity |

g/L |

3.77 |

4.71 |

|

TS |

g/L |

54.97 |

23.65 |

|

TSS |

g/L |

11.40 |

3.72 |

resulting in a lighter coloration and higher turbidity when compared to effluent 2, which is older and goes through a decantation process in the tank.

The polluting power of this effluent can be attributed to the high organic load, observed in the large concentration of BOD5 and COD, organic nitrogen, and phosphorus content. Ranade and Bhandari [7] attributed this to the presence of lipids, sugars, tannin, pectin and lignin, the high concentration of phenolic compounds as well as phosphate salts.

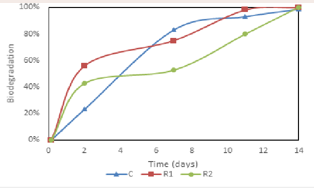

The BOD5/COD ratio is a good indicator of the biodegradability of wastewater, for effluent 1 this ratio is 0.38 and for effluent 2 is higher, 0.53, due to the degradation and sedimentation while stored. A higher ratio (>0.3) indicates a high biodegradable organic compounds fraction, and a biological treatment may be effective. The biodegradability is confirmed by the Zahn-Wellens test shown in Figure 3.

Figure 3: Zahn-Wellens Biodegradation Test Curves.

In the Zahn-Wellens test, activated sludge from the local domestic wastewater treatment unit is used to degrade an amount of the two effluents (R1 and R2). The third reactor (C), for control is used to validate the results using ethylene glycol as a control substance to determine the sludge quality and adaptability. A blank reactor with the same conditions as determined for the OECD Guideline [7], was settled with no biodegradable substance to reduce influences in the COD determination by a colorimetric method due to parallel reactions and variations in the activated sludge. Due to the good adaptability of the activated sludge, in 14 days all the effluents were completely degraded.

Another crucial aspect is its acidity due to the presence of organic acids, capable of changing the pH of a waterbody if discarded without treatment. The high amount of organic and inorganic compounds that work as nutrients can destabilize the natural condition on the recipient waterbody, favoring the growth of algae in the process acknowledged as eutrophication.

When compared with the Emission Limit Values in the discharge of wastewater present in Decree-Law No. 236/98 of 1st August [12], all parameters analyzed in the characterization of both effluent 1 and 2 are above the established limits. This confirms the need to implement a treatment unit for industrial effluents.

Analyzing previous works with effluents with a polluting load close to that found in effluents and from nearby matrices, a promising route for treatment is the reduction of solids and organic matter by pre-treatments such as coagulation/ flocculation and flotation, followed by a biological reactor, and a tertiary treatments such as filtering and polishing the effluent until the emission limit values are respected in their entirety.

WATERBODY QUALITY

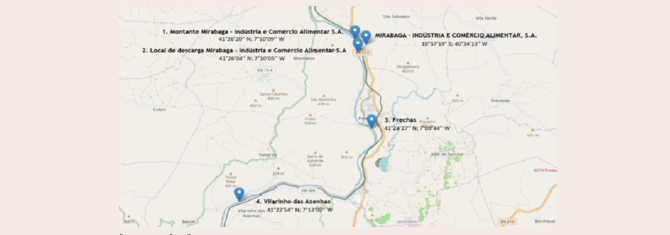

To ensure the environmental safety of the river that receives the effluent of the factory, the water was collected in four different points of the river Tua (Figure 4),

Figure 4: Tua river sampling points localization.

located in the district of Braganza, Portugal.

The first was upstream from the factory to observe the water quality before the factory. The second sample was collected in the place where the factor poured the wastewater. The third and fourth points were downstream the factory to evaluate the depuration of a pollution charge which the factory relies on the river. Point four also corresponds to a pluvial beach accessible to the local population used for recreation and other activities.

The impact of industrial wastewater disposal can be seen in point 2: the data shows a rise in parameters COD and BOD when compared with point 1, as noted in Table 2.

Table 2: River water characterization in different locations.

|

Parameter |

Unit |

Collected point |

|||

|

1 |

2 |

3 |

4 |

||

|

Temperature* |

ºC |

16.2 |

18.8 |

17.3 |

17.5 |

|

Conductivity* |

μs/cm |

47.3 |

56.5 |

46.5 |

45.9 |

|

TDS* |

mg/L |

26.9 |

31 |

26.3 |

25.7 |

|

Dissolved Oxygen* |

% |

95.4 |

87.1 |

92.5 |

94.1 |

|

pH |

- |

6.4 |

6.14 |

6.2 |

6.17 |

|

Turbidity |

NTU |

12 |

27 |

11 |

14 |

|

BOD5 |

mg O2/L |

< 10 |

30.57 |

< 10 |

< 10 |

|

COD |

mg O2/L |

13.58 |

86.07 |

15.23 |

24.27 |

|

TSS |

mg/L |

6.9 |

28.9 |

5.2 |

7.5 |

|

TDS |

mg/L |

61.7 |

111.3 |

52.4 |

49.4 |

|

Ammoniacal Nitrogen |

mg/L |

0.44 |

0.31 |

0.27 |

0.34 |

|

Nitrates |

mg/L |

0.69 |

0.39 |

0.09 |

0.51 |

|

Total Phosphorus |

mg/L |

0.02 |

0.01 |

0.02 |

0.03 |

|

Phenolic Compounds |

mg/L |

<DL |

<DL |

<DL |

<DL |

|

Aromaticity |

mg/L |

13.16 |

23.17 |

13.53 |

14.76 |

*: parameters measured in the local where the samples were collected

<DL: lower than the method detection limit.

As no effluent characterized previously in this article is released in the waterbody, these alterations in the values were due to the water used to cool the streams out the separation processes and the water recovered in the solvent recuperation process, the effluent pass for a cooling step before being poured in the river.

The waterbody has a good depuration capacity, with the parameters returning lower levels of organic matter as seen in point 3. In point 4, some attributes increase again due to the human activity present in the area.

The water quality was assured by comparing the results with the Portuguese water legislation, Decree-Law No. 236/98 of 1 August [12], considering the maximum recommended value for irrigation and bathing waters, none of the parameters obtained values higher than those allowed.

CONCLUSION

In order to obey the Portuguese legislation, the olive pomace oil extractor industry studied cannot dispose of industrial effluents as it is produced due to the amount of organic matter and other substances. The effluent must be treated before disposal, to this; a wastewater treatment plant must be constructed and dimensioned based on the amount produced daily and the characterization proved by the article. To provide an adequate environmental management to this factory, the waterbody must be monitored as required by current legislation, in the parameters determined by it and sampling frequency required for the maintenance of the quality validated in May 2021.

REFERENCES

- Figueiredo F, Maia F, Pereira JA, Ramalhosa E, Ramos AD, Gomes P,et al. Ecoeficiência e Ecogestão no Setor do Azeite: Uma Avaliação deCiclo de Vida. 2015.

- Brito RF. Valorização integrada de resíduos e subprodutos da extração do azeite: Extração e caracterização de compostos bioativos do bagaço de azeitona. Dissertação apresentada ao Instituto Superior de Engenharia da Universidade do Algarve para obtenção do Grau de Mestre em Tecnologia de Alimentos. 2016.

- Petrakis C. Olive oil extraction. Olive Oil, AOCS Publishing. 2006

- Seçmeler Ö, Galanakis CM. Olive fruit and olive oil. Innovations inTraditional Foods. 2019; 193-220.

- Toscano P, Montemurro F. Olive mill by-products management. Olive Germplasm - The Olive Cultivation, Table Olive and Olive Oil Industry in Italy. 2012.

- MMP de Faro Ferraz. Contribuição para o estudo do tratamento de efluentes de lagares de azeite. Dissertação para obtenção do Grau de Mestre em Engenharia do Ambiente. 2012.

- Ranade VV, Bhandari VM. Industrial wastewater treatment, recycling, and reuse. Industrial Wastewater Treatment, Recycling and Reuse. 2014: 1-80.

- Eaton AD. Standard Methods for the Examination of Water and Wastewater. 2005.

- OECD Guideline for Testing of Chemicals. Test Guideline 302 B: Zahn-Wellens/EMPA Test. 1992.

- Moral PS, Méndez MVR. Production of pomace olive oil. Grasas y Aceites. 2006; 57.

- Freitas MR. Avaliação do potencial energético dos resíduos sólidos dos lagares do Alentejo. Dissertação apresentada ao Instituto Superior de Engenharia da Universidade Técnica de Lisboa para obtenção do Grau de Mestre em Agronomia. 2007.

- Decreto-lei n.o 236/98 de 1 de agosto. Diário da República: I série A,Nº 176.