Investigating Eco-Friendly Concrete in the Construction Industry in Order to Improve the Circular Economy - A Literature Review

- 1. Master's Degree in Construction Management, School Engineering, Khaje Nasir Toosi University, Tehran, Iran

- 2. Master's student in Construction Management, School Engineering, Mehr Alborz University, Iran

- 3. Assistant professor, Environment department, engineering faculty, Mehr Alborz University, Iran

- 4. Faculty of Engineering, Tarbiat Modares University, Iran

Abstract

The construction industry, responsible for significant greenhouse gas emissions and heavy natural resource consumption, is under growing pressure to adopt sustainable practices. The increasing demand for infrastructure, driven by rapid population growth, has intensified the environmental impact of traditional materials like concrete. However, incorporating recycled materials into concrete production presents an opportunity to reduce both energy use and greenhouse gas emissions, improving the sustainability of construction projects. This study examines literature from 2018 to 2024, highlighting key trends, challenges, and opportunities in the adoption of environmentally friendly concrete, and proposes strategies to promote circular economy principles in the industry. This study highlights the benefits of using ceramic waste as a partial replacement for cement and fine aggregates in sustainable mortar production, showing improvements both in mechanical performance and environmental impact. By substituting these materials, the environmental footprint of Portland cement can be reduced by up to 30%. Additionally, a mix containing 70% fly ash and 100% recycled aggregates achieves a compressive strength of 35 MPa. This approach not only lowers natural resource use by 50% but also enhances construction waste management. Furthermore, carbon emissions could be reduced by as much as 40%, advancing environmental sustainability. Experimental findings reveal that the inclusion of silica fume and fly ash improves concrete's mechanical properties while increasing its permeability. The use of ceramic waste and recycled materials in concrete offers a cost-effective, resource-saving solution that promotes sustainable and circular construction. These findings can serve as a valuable foundation for shaping policies on sustainable construction in various regions.

KEYWORDS

- Circular economy;

- Greenhouse Gases

- Sustainability

- Construction industry

- Recycled materials

CITATION

Partonia P, Heidarian S, Dezvareh GA, Darban AK (2024) Investigating Eco-Friendly Concrete in the Construction Industry in Order to Im- prove the Circular Economy - A Literature Review. Chem Eng Process Tech 9(2): 1093.

INTRODUCTION

The construction industry heavily consumes natural resources and generates significant amounts of solid waste. As population growth accelerates and housing demand rises, the pressure to adopt sustainable practices in the sector has increased [1,2]. In this framework, the circular economy represents a novel and sustainable strategy for managing resources and mitigating environmental impacts. Key challenges in this area include the overuse of construction materials, waste production, and elevated pollution levels [3]. Traditional building materials cause damage to natural resources and contribute to environmental degradation during construction. Moreover, a lack of focus on sustainability in building design leads to increased maintenance costs and lower quality of life for occupants. In contrast, the circular economy promotes extending product lifecycles and minimizing waste through material reuse and recycling. This approach offers a restorative alternative to the traditional linear economy model [4]. In 2021, Matthew and his team released a study called "Recent Advances in Geopolymer Technology: A Potential Eco-Friendly Solution in Construction Materials." The research focused on geopolymer concrete technology, highlighting its superior mechanical properties and durability over traditional concrete. The study also explored future development opportunities, such as novel geopolymer formulations and their successful use in civil engineering and architecture. Additionally, it addressed the potential for commercializing and expanding the use of this technology [5]. In 2022, Jessen and colleagues published a study titled "Utilisation of Ceramic Waste Aggregate and Its Effect on Eco-Friendly Concrete." Their research examined how recycled ceramic waste aggregates (RWCA ) can replace both fine and coarse aggregates in concrete. The study found that although substituting RWCA partially decreases the workability of concrete, it significantly improves compressive strength, flexural strength, and durability [6]. In 2023, Robert conducted a study titled "A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway Towards a Circular Economy." This research utilized bibliometric analysis with the software "Bibliometrix" (version 4.1.3) to explore various waste materials. The study found a significant drop in research focus on elastics, textiles, and ceramics. It recommends implementing a holistic approach to evaluating the full lifecycle of materials to enhance support for sustainable construction practices [7]. This study explores the use of environmentally friendly materials within the construction industry and evaluates strategies for promoting the circular economy through their integration. It seeks to pinpoint challenges and opportunities in adopting these materials and provides recommendations to facilitate a shift toward more sustainable construction methods. As the emphasis on sustainability in construction grows, the insights from this research offer crucial guidance for policymakers, architects, and contractors.

METHODOLOGY

This study investigates the use of environmentally friendly materials in the construction industry and evaluates their role in promoting the circular economy. It reviews current trends, identifies research gaps, and offers recommendations to enhance the application of these materials. By analyzing literature from 2018 to 2024, this review-based research provides a comprehensive overview of eco-friendly materials and circular economy practices. Table 1 details the findings from a review of relevant keywords across reputable databases.

Table 1: Number of Articles Published Based on Keywords and Sources over the Past Six Years

|

Keywords |

Year |

Google Scholar |

Science Direct |

Emerald |

|

eco-friendly materials |

2018-2024 |

5,34,000 |

1,25,908 |

2,323 |

|

construction industry |

2018-2024 |

8,28,000 |

2,95,552 |

28,955 |

|

sustainable construction |

2018-2024 |

1,87,000 |

2,89,918 |

19,929 |

|

circular economy |

2018-2024 |

38,500 |

60,478 |

5,285 |

|

waste management |

2018-2024 |

5,06,000 |

2,32,696 |

17,502 |

Articles were selected based on criteria including publication date, type, citation count, and journal reputation. This systematic review provides a comprehensive analysis of eco-friendly materials in the construction industry, with the potential to identify strategies for advancing the circular economy.

RESULT AND DISCUSSION

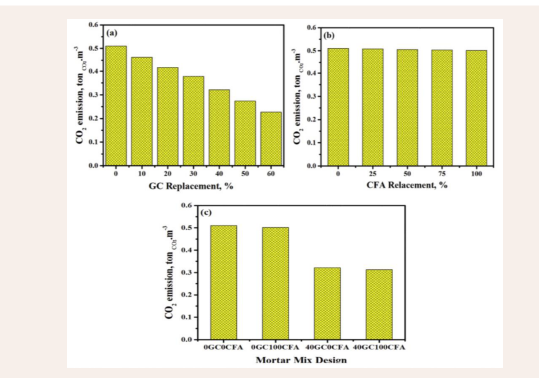

In 2020, the study "Ceramic Waste as Low-Cost and Eco-Friendly Materials in Sustainable Mortar Production" investigated the use of ceramic waste as a partial substitute for cement and fine aggregates in mortar. The research evaluated how incorporating ceramic waste affects the mortar's long-term performance, mechanical properties, and durability, as well as its environmental advantages. In this study, ceramic waste was employed both as a supplementary cementitious material and as fine aggregates. The findings, illustrated in Figure 1, show that replacing Portland cement (OPC) with these waste materials leads to a notable reduction in greenhouse gas emissions.

Figure 1: a) Greenhouse gases release of GC replacement, b) Greenhouse gases release of CFA replacement, c) Greenhouse gases release of sample 40GC100CFA.

This effect is significant even at minimal replacement levels. The results indicate that using ceramic waste as a partial substitute for cement can effectively mitigate environmental impacts. This method demonstrates a greater reduction in greenhouse gas emissions compared to using waste materials as fine aggregates, making it a promising sustainable solution for the construction industry. Mortars that include ceramic waste demonstrate enhanced performance and offer substantial technical and environmental benefits. The incorporation of ceramic waste effectively reduces carbon dioxide emissions, conserves energy, cuts electricity use, and lowers fuel consumption. As a result, this method not only reduces construction costs but also contributes to greater global sustainability [8].

In 2021, the study "Green Concrete for a Circular Economy: A Review of Sustainability, Durability, and Structural Properties" was published. This research investigated the effects of using green concrete (GG ), which replaces ordinary Portland cement with supplementary cementitious materials (SCMs ) and recycled concrete aggregates (RCAs ), on environmental sustainability and mechanical performance. The study provides a comprehensive review of the literature available in the Scopus database. The study reveals that incorporating supplementary cementitious materials can lessen the environmental impact of ordinary Portland cement. When used at optimal levels, these materials provide the necessary concrete strength for different applications. However, they should not be used at temperatures above 400°C. Beams made with 70% fly ash (FA ) or 100% recycled aggregates also show satisfactory performance as Portland cement substitutes. These findings highlight how green concrete can significantly support a circular economy by reducing natural resource use and enhancing the recycling of construction waste through supplementary materials and recycled aggregates. This method significantly cuts carbon emissions and enhances environmental sustainability while maintaining concrete's mechanical integrity. By carefully adjusting cement substitution levels, it is possible to produce high-quality concrete for various construction needs. Consequently, this research promotes material reuse and reduces dependence on raw resources, contributing to the advancement of a sustainable and circular construction system [9].

The 2017 study, "Utilization of Recycled Materials for Low- Carbon and Cost-Effective Concrete Construction," investigated the use of natural and partially replaced recycled aggregates in cement-based concretes to minimize carbon footprints and enhance resource efficiency. It also explored how supplementary cements can reduce carbon dioxide emissions and improve concrete properties. The research involved testing compressive strength and carbon dioxide emissions in concrete mixtures with different proportions of recycled aggregates and recycled glass sand. The results highlight the effectiveness of CEM II/B-M and CEM V/A cements in producing both low-carbon and economically viable concrete. Adding silica fume and fly ash has enhanced the properties of concrete. Tests reveal that these modified mixtures exhibit better permeability than those made with ordinary Portland cement, though the latter provides greater resistance to carbonation. This study underscores the benefits of strategically using recycled materials to cut carbon dioxide emissions and reduce production costs [10].

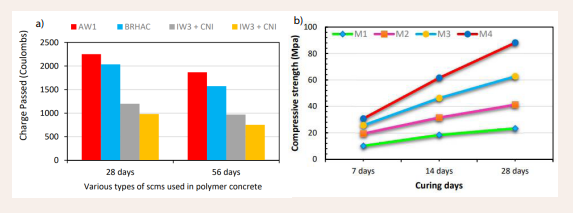

The study "Utilization of Polymer Concrete Composites for a Circular Economy: A Comparative Review on Waste Recycling and Utilization" investigates the potential of polymer concrete composites as supplementary cementitious materials. It seeks to establish a circular economic model for their application.

The research highlights that polymer concrete composites, which offer a sustainable alternative to conventional concrete, can effectively incorporate industrial and agricultural waste, improving building quality. To fully leverage their economic, technological, and environmental benefits, it is essential to develop targeted strategies and encourage collaboration among construction organizations for the adoption of sustainable concrete in large-scale projects. Future research should focus on creating sustainable binding materials and formulating guidelines for the effective use of industrial waste to cut energy consumption and carbon emissions. Implementing a circular economy model could improve polymer design and optimize local resources [11]. Figure 2 demonstrates chloride penetration at different curing ages for various supplementary cementitious materials (SCMs) and compares the compressive strength of several 3IW cement replacements over various curing durations.

Figure 2; a) Chloride penetration at various curing ages for different SCMs, b) Compressive strength of various IW3 cement replacements on various curing days

CONCLUSION

Based on this study's findings, several conclusions can be made:

- Incorporating ceramic waste as a partial substitute for cement and fine aggregates in sustainable mortars improves both their mechanical properties and durability, yielding notable environmental benefits. The study shows that even with minimal replacement levels, there is a substantial decrease in greenhouse gas emissions. This underscores the significant potential of waste materials to alleviate the environmental impact of the construction sector. Consequently, using ceramic waste emerges as a cost-effective and sustainable strategy that not only reduces construction expenses but also enhances overall industry sustainability.

- Supplementary cementitious materials can decrease the environmental impact of Portland cement by as much as 30%. Beams incorporating 70% fly ash and 100% recycled aggregates exhibit commendable mechanical properties, achieving compressive strengths of up to 35 megapascals. The study highlights that strategically substituting cement with these materials produces high- quality concrete suitable for construction purposes. This approach also reduces natural resource consumption by 50% and manages construction waste more effectively. Furthermore, it results in a 40% reduction in carbon emissions and promotes environmental sustainability, supporting the advancement of sustainable and circular construction practices.

- Incorporating natural and partially recycled aggregates with supplementary cements can greatly diminish the carbon footprint and enhance the efficiency of natural resource use in concrete production. Research indicates that CEM II/B-M and CEM V/A cements are particularly effective in creating low-carbon, cost-efficient concrete. Adding silica fume and fly ash enhances both the mechanical properties and permeability of concrete; however, ordinary Portland cement remains more resistant to carbonation. Utilizing recycled materials strategically is crucial for reducing production costs and carbon dioxide emissions, thus promoting more sustainable concrete practices.

Composites that utilize industrial and agricultural waste offer significant improvements in building quality. To fully leverage the economic and environmental benefits of these materials, it is crucial to establish collaborative strategies among construction organizations for promoting sustainable concrete in large-scale projects. Future research should focus on developing eco-friendly binders and creating guidelines for efficient waste management to reduce energy consumption and carbon emissions. Implementing a circular economy model will optimize local resources and support sustainability goals in the construction sector. By encouraging cooperation among stakeholders and applying the strategies proposed in this study, we can enhance environmental sustainability, reinforce circular economy practices, and ultimately lower construction costs.

REFERENCES

- Ghisellini P, Cialani C, Ulgiati S. A review on circular economy: the expected transition to a balanced interplay of environmental and economic systems. Journal of Cleaner production. 2016; 114: 11-32.

- Adams KT, Osmani M, Thorpe T, Thornback J. Circular economy in construction: current awareness, challenges and enablers. Proceedings of the institution of civil engineers-waste and resource management: 2017; 170: 15-24.

- Pomponi F, Moncaster A. Circular economy for the built environment: A research framework. Journal of cleaner production. 2017; 143: 710-718.

- Gasparri E, Arasteh S, Kuru A, Stracchi P, Brambilla A. Circular economy in construction: A systematic review of knowledge gaps towards a novel research framework. Frontiers in Built Environment. 2023; 9: 1239757.

- Sambucci M, Sibai A, Valente M. Recent advances in geopolymer technology. A potential eco-friendly solution in the construction materials industry: A review. Journal of Composites Science. 2021; 5: 109.

- Magbool HM. Utilisation of ceramic waste aggregate and its effect on Eco-friendly concrete: A review. Journal of Building Engineering. 2022; 47: 103815.

- Haigh R. A decade review of research trends using waste materials in the building and construction industry: a pathway towards a circular economy. Waste. 2023; 1: 935-59.

- Samadi M, Huseien GF, Mohammadhosseini H, Lee HS, Lim NHAS, Tahir MM, et al. Waste ceramic as low cost and eco-friendly materials in the production of sustainable mortars. Journal of Cleaner Production. 2020; 266: 121825.

- Al-Hamrani A, Kucukvar M, Alnahhal W, Mahdi E, Onat NC. Green concrete for a circular economy: A review on sustainability, durability, and structural properties. Materials. 2021; 14: 351.

- Bostanci SC, Limbachiya M, Kew H. Use of recycled aggregates for low carbon and cost effective concrete construction. Journal of Cleaner Production. 2018; 189: 176-196.

- Alhazmi H, Shah SAR, Anwar MK, Raza A, Ullah MK, Iqbal F. Utilization of polymer concrete composites for a circular economy: A comparative review for assessment of recycling and waste utilization. Polymers. 2021; 13: 2135.