Carbon Negative Genetically Engineered Foods with Potato Recombinant Genes

- 1. CEO, Executive Chairman, President of Microbial Biocatalyst International Inc, and Inorgcarbdiesel Inc, 300230, Houston TX 77230, USA

Abstract

We have created the Carbon Negative genetically engineered potato foods. The host for the expression is the in the white tubular mushroom of the Borovik family also known as porcini, king bolete, or cèpe. Said mushrooms are Carbon Negative as they are cultivated at the sterile corporate facility on the biomass of the Acetogens biocatalysts used for the manufacture of Carbon Negative fuels and Carbon Negative fuel mixtures as the mushrooms growth medium. This is the intelligent response of the Author of this original article to the attempted murder he was subjected to by SHELL at 9494 Southwest Freeway in Houston TX (HPD report is available for reference).

Keywords

Carbon Negative Genetically Engineered Potato; Expression is the in the White Tubular Mushroom; Sterile Corporate Facility; Biomass of The Acetogens Biocatalysts; Intelligent Response.

INTRODUCTION

Potatoes were first cultivated by the Inca Indians in Peru between 8,000 and 5,000 B.C. The ancient Incas even used the time it took to cook a potato as a way to measure time—highlighting its importance in their culture. While potatoes eventually reached the northern colonies, they gained popularity only after Thomas Jefferson served them at the White House. His endorsement helped the crop gain wider acceptance, a trend further boosted by Irish immigrants who had strong ties to potato farming (https://www.potatopro.com/potato-markets/world). We have published our unmatched expertise of expression of some recombinant meat genes (bovine myoglobin and sheep myostatin) in the tubular white mushrooms of the Borovik family [1,2]. The shish kabobs [1-4], made by us for our testing team of my Corporate Senior Executive staff were eaten completely even without the FDA approval of our genetically engineered meats (we advised testing team on that prior to testing) and we were asked for more of such food by the eaters regardless of our timely warning. This our positive experience made us try another recombinant genes. We have expressed the potato, tomato and eggplant recombinant genes in the same host in our preparation to the Global Starvation in the next 10-25 years as we do anticipate on our planet Earth due to the overproduction of the air CO2 due to the dominance of the international petroleum corporations on the fuel market which is the cause of the increase of the air CO2 content in the air gas blend due to consumption of Gasoline and Diesel fuel by customers World-wide including those who work for the commercial structures as we have described that before and we have offered the ultimate solution for that problem of creation of the ecological disaster on our planet Earth due to the enormous accumulation of the air CO2 (the product of the international petroleum corporations) via the suggested dominance of our Carbon Negative fuel corporations on the global World market now occupied by the international petroleum corporations [2-13]. The density of the CO2 is 1.97 g/m3 and its air gas blend concentration increases constantly. It reaches now the levels of above 450 ppm [5-15]. Air CO2 is among the heaviest gases of the air blend along with the minor amounts of the inert gases (krypton, argon, neon, helium, etc.) which are the heaviest in the air gas blend. Due to the gravity force the air CO2 spreads on any surface laying underneath of the approximately 400 miles wide air gas blend layer (atmosphere) over our planet Earth due to Earth’s gravity force. One side of this layer gets in touch with the Space vacuum surrounding our planet and the other side is presented by the air gas blend heaviest gases spreading over the Ground and the surface of the seas / oceans. We would remind our article readers that the air CO2 has the highest density of 1.97 g/m3 along with the low qualities of the inert gases also as the part of the air gas blend. The average air gas blend density of about 1.22 g/ m3 (https://www.sciencedirect.com). This is the core of the stated above environmental problem. The air CO2 selectively like just any CO2 absorbs the infra-red energy of the Sun light (photons) immediately converting it to heat via the vibration of the CO2 molecules [5-14]. The photons cause vibration of the air CO2 molecules and that vibration is the source of said heat [5-14]. Due to its density the air CO2 covers Ground (Ground is the natural refuge of the all falling water - from melting ice/snow, rains, etc.) and over the sea / ocean salt water surface causing the evaporation of the extra fresh water vapors to the air gas blend [5-14]. As above said air CO2 converts Sun light into heat energy therefore heating the surfaces of the Ground and of the salty sea / ocean water causing evaporation of the extra fresh water vapors amount to the air gas blend. Such evaporation of the fresh water vapors from the Ground and from the sea / ocean salty water causes formation of clouds which under the proper conditions give rains destroying the property on the right bank of Pacific ocean in California(the Pacific coast of California) causing tremendous damages [XX]. In TX rains bother mostly the homeless people who are the product of the dominant capitalist market economy. You can notice now that the weather in Houston TX has changed significantly over the last 28 years. The Author came to work in Houston in 1998 (the beginning of said 28-year period of the weather changes due to the Global warming [16,17]). in 1998 the Author has enjoyed the bottomless blue Houston sky with no any traces of clouds. What do we have now? The sky in Houston is always cloudy due to said fresh water vapors condensed now in clouds covering all Houston skies. Rains are possible, but the problem of the fresh water loss to the Space vacuum is now the global environmental problem of our planet making the most educated venture capitalists to search now the ways to improve the construction of the spacecrafts to make them suitable to relocate the part of the Humankind to other planets similar to Earth by the fresh water content, the atmosphere chemical composition and the temperature profiles [17,18]. Now this article is devoted to description of some genetically engineered potatoes. The diversity of potato species was discussed [19], with respect to geographic distribution and potato species variations. Commonly cultivated potato varieties include tetraploid (2n = 4x =48) with a basic potato chromosome number of 12, while there are cultivated species at the diploid (2n = 2x = 24) to the pentaploid (2n =5x = 60) levels. The triploid and pentaploid species grow only on highland plateaus and slopes of the Andes, but diploid potato species are grown more widely and also used for breeding of the tetraploid varieties. Wild and cultivated potato genetic resources provide a variety of reproductive and genetic features associated with species differentiation and breeding applications. The number of species varies among the taxonomic classifications and around 200 wild species have been identified [20-22]. The majority of the 200 potato wild species are diploid, and many of these diploid species can be crossed with tetraploids using 2n gametes which can be easily found in potato genetic resources both in cultivated and wild species [23-26] as stated in [27]. Potato (Solanum tuberosum L.) is the third most important food for human consumption behind wheat and rice, and it is among the top horticultural crops [28]. Two thirds of the annual yield is marketed fresh, while the remainder is processed for snack and other industrial food products including animal feed, adhesives, pharmaceuticals, wood, and textile commodities [28,29]. In 2019, 17.5 million hectares of potatoes were cultivated World-wide yielding 370.5 million tons (Table 1).

Table 1: Area harvested in hectare (1 ha = 2.47 acres) and production in tons for each continent and World’s total. Data are of year 2019 and they were obtained from Food and Agriculture Organization Database (http://agmatix.com).

|

Regions |

Area harvested (ha) |

Production of potato (tons*) |

|

Africa |

1,763,848 |

26,534,489 |

|

America (North & South) |

1,539,393 |

45,083,546 |

|

Asia |

9,298,106 |

189,810,377 |

|

Europe |

4,696,336 |

107,264,935 |

|

Oceania |

43,303 |

1,743,234 |

|

TOTAL |

17,340,986 |

370,436,581 |

Asia is the World’s largest potato producer and consumer with more than 9 million hectares (ha) (1 ha = 2.47 acres) grown and 189 million tons harvested. Europe produced almost a third of the world total harvest (107 million tons) that was grown on more than 4.5 million hectares. Africa and North America have a similar area dedicated to potato cultivation while North American production almost doubles that of Africa [30,31].

*1 ton is 1,000 kilos. 1 kilo = 2.20462262 pounds.

The nuclear DNA content of sweet pepper (Capsicum annuum L. var. annuum, 2n = 24) has been measured by flow and image cytometries but the DNA content of each chromosome of this species has not yet been regarded. The DNA content of individual chromosomes has been quantified by flow karyotyping technique which requires a great quantity of intact metaphasic chromosomes and methods allowing the characterization of individual chromosomes. Getting the adequate number of metaphases can be difficult in some species like C. annuum. In order to estimate the DNA content of each C. annuum var. Annuum flow and image cytometries were associated with the cytogenetic methodology. For that purpose the DNA amount (2C = 6.90 pg) was established by the flow cytometry. Integrated optical density (IOD) values were calculated by image cytometry for each Feulgen stained metaphasic chromosome. Then, by distributing the correspondent metaphasic value (4C=13.80 pg) proportionally to the average IOD values. The following chromosomal DNA contents were obtained in pg: 0.74 (chromosome 1), 0.67 (2), 0.61 (3, 4), 0.60 (5), 0.59 (6, 7), 0.58 (8), 0.57 (9), 0.56 (10) and 0.39 (11, 12) [32]. This article along with the previous one on the bovine and sheep muscles recombinant proteins expressed in the genetically engineered mushrooms B. edulis comes in series of articles devoted to our corporate efforts to create plenty of genetically engineered foods to become US Government approved and then to be sold at our new type of gas stations along with the Carbon Negative fuels and Carbon Negative fuel mixtures to out valuable customers. This is not very expensive food for the Humankind during the time which will take the removal of the international petroleum corporations from the World’s fuel market and therefore removal of the air CO2 content increase is the cause of the Global warming and the fresh water loss by our planet Earth. The Global starvation of the Humankind due to the anticipated by my Corporations shortness of the fresh water corresponds to the shortness of the livestock and crops manufacture as the cause of the anticipated Global Humankind starvation [14]. So my Corporations are in charge to cope with that.

MATERIALS AND METHODS

Electrotranformation

We have used our patented in the Russian Federation in 1992 Generator for the Electrotransformation / Electrofusion [33,34], for the electrotranformation of the recombinant genes to the Carbon Negative Boletus edulis (the copy of that generator was first purchased by the US corporation and then presented back to Professor Dr. MV Tyurin). We cloned the recombinant genes of potato [35,36]: ZF-HD encoding homeobox domain-containing protein (the nucleotide numbers are the same everywhere for potato, see below], proteins of unknown function (encoded by genes with sequence numbers 23702...23778, 23868...25318, 26412...26825, 26899...27122, 27145... 27648, 31221...31347, 31530...31609, 33372...33481, 33570...33938...31609, 33372...33481, 33570...33938, (NAM)-like protein (DNA sequence ## 37297...38007, 38656...38960, 39577…39772), hypothetical protein (DNA sequence ## 66605…67597, 85996…86217, 86357...86518, 86635…8710), putative RNA-dependent RNA-polymerase (DNA sequence ## 119445…120459, 121548…121698, 122344…124208, 126846…127418), putative CAAX amino terminal protease (DNA sequence ## 157033…157074, 157235...157341, 157734…157825, 159097…159189, 159338...159387 159531…159664, 159795...159877, 159965.. 160072, 160500...160591, 160841…161053), putative disease resistance protein (DNA sequence ## 213106…213814, 213903…214164, 214260...215379, 215523…215598, 215685…215800), putative disease resistance protein (DNA sequence ## 228119…230739, 230835...231948), putative disease resistance protein (DNA sequence ## 240961…242214, 242258...243564, 243660…24478, 244836…244940), late blight resistance protein R1 (DNA sequence ## 379174…379326, 379598…380729, 380823…383479), putative disease resistance protein (DNA sequence ## 389918…390039, 390224…390287, 390338...391466, 391562…394164), putative disease resistance protein (DNA sequence ## 401566…404210, 404303...404952, 405054…405385), putative regulator of chromosome condensation RCC1(DNA sequence ## 411076...411123, 411658...411744, 411860...411925, 412576…412665, 412948…413028, 413151...413309, 413420…15525, 416819…416859, 416947…417124). Said DNA sequences were then electrotransformed to Boletus edulis strain we have used herein flanked each by Boletus edulis nucleotide sequences 8161...10981 and 10982...13661 with the electrotransformation of the recombinant proteins using our Electrotransfrmation/Electrofusion Generator [33,34]. The sequences encoding these proteins were separated by “aaaaa” nucleotide sequences inserted between the genes in the DNA sequences encoding other potato proteins [15-40]. Despite the energy boost you may receive from eating potatoes they contain a lot of starch, a type of carbohydrate with the monomer of alpha-glucose toxic for Diabetics. The starch amount depends on the potato type and size/weight of them. Carbohydrates are the main source of glucose (sugar) in the human body. The body uses glucose for energy. However the starch from any source, potato, corn, etc. has damaging effect on the people suffering from Diabetes I and II. Fortunately for the health of the testers (even sick with both types of Diabetes) but unfortunately for the taste of the recombinant potato proteins expressed in our strain of Boletus edulis the recombinant potato genes we have used (above) do not have the DNA sequences encoding formation of potato starch and create the taste exactly of potato or resemble it very much as the RESULTS section of this original article tells to the readers.

Summary

As we have noted elsewhere there is no limitation of the size of the genetic constructs we may use to introduce into the target sells of the chosen expression system expressing the recombinant genes due to the use of our unique Electrotransformation / Electrofusion Generator [35 40]. Therefore we have introduced into Boletus edulis the whole genome of the tomatoes. The recombinant tomatoes are shown in Figure 1.

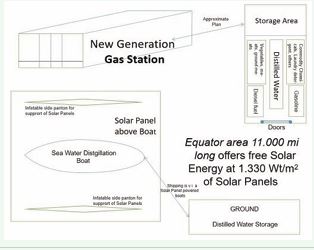

Figure 1 Our new type of gas stations [44], selling not only the Carbon Negative fuels but also the distilled water we will produce in abundance from the sea water using Equator areas of Earth for the best insulation of our solar panels batteries combined with the alkaline batteries for 24/7/365 operations we plan to purchase at substantial discounts from the national shipyards decomposing the submarines of various types along with the DC motors from the same submarines to power our distillation and shipment boats / ships.

We flanked their genomes by the nucleotide sequences of Boletus edulis with the nucleotide numbers 2101...4501 and 4502...8041).

Electrotransformation of Boletus edulis with the recombinant DNAs of said potatoes

The Electrotransformation procedure of Boletus edulis was performed as described before [17]. Herein is the quick summary of that process. Under the horizontal laminar hood (http://airscience.com) we have segregated the mature (250 g or slightly above that) single Boletus edulis spores in their tubula using the sterile disposable scalpel. Said spore mass was transferred into the sterile beaker. The beaker size depends on the mass of the mushroom. For the Boletus edulis of about 250 g mass the beaker size was 100 ml. For bigger mushroom size we recommend beakers of higher volume. The role of the beaker is to accommodate not only the separated from the mushroom spore mass in tubules but also to accommodate 12 times the volume of the medium for the mushroom spore germination.

We used the medium for the mushroom Boletus edulis

spore germination of the following composition, g/l: Meat extract (Difco) 10.0

Soybean Extract (Sigma) [25] 10.0

Glucose 20.0

Na2HPO4 47.76 mM.(unhydrous dibasic) 6.78

KH2PO4 22,044 mM.(monobasic); 3.0

NaCl; 8.556 mM. 0.5

NH4Cl; 18.695 mM 1.0

Milli-Q water: 938.61 g or up to 1 L pH 6.9 +_0.2

before autoclaving for 35 min at 1.5 atm (kg/m2) or 116,523.75 Pa.

The medium was chilled to abut 30oC before it’s edition to the mass of spores / tubules. The diluted with said medium spores and tubules were incubated at 30oC for four and a half hours (4.5 h). After that incubation time the spores started to germinate making the bacteria-like in their shape structures suitable for the electrotransformation using our patented Electrotransformation / Electrofusion Generator [33,34]. Before said medium addition the mass of tubules with spores was cut multiple times, as much as possible, with the sterile scalpel (http:biologyproducts. com), treated using that scalpel to mix the content several times to provide the homogeneity of the tubules / spores mass before the medium would be added. For the 250g mushroom size tubules / spores we have added 80 ml of said medium. The added medium was mixed with the treated by sterile scalpel mass of the tubules / spores and then transferred to the 15 ml centrifuge tubes by about 5 ml. Said plastic centrifuge tubes were placed in the thermostated at 30oC shaker set at 200 rpm shaking speed for 4.5 hours.Upon finishing of the shaking we collected the germinated spores of Boletus edulis by centrifugation. Collected germinating sores of Boletus edulis from each 15 ml plastic centrifuge tube were transferred to the 0.5 microliter poplypropylene tube served as the ET cuvette [35-40], for the use of our Electrotransformation / Electrofusion Generator. Said cuvettes were placed at the ice block per the electrotranformation (ET) procedure as discussed at [35-40], and subjected to the procedure of ET. The ET was conducted by the application of 3.5-4.0 ms square pulse at the electric field strengths of 12.5 to 14 kV/cm stepping over 0.5 kV/cm each time. Immediately after the ET the contents of the ET cuvettes were diluted with 0.5 ml of the same medium used to germinate the spores of Boletus edulis. The diluted suspensions of the ET spores were then left at 30oC for 1.5 hour at 30oC and then the content of each 0.5 ml ET cuvette was transferred into the 15 ml centrifuge tubes with addition of 5 ml of the medium used for the germination of spores (as above).The amount of 5 ml of the same medium was added to each tube, pellets were mixed with the medium by shaking and the tubes were transferred to the sterile incubated at 30oC cultivation boxes for inoculation of soil filled by 10 cm thick layers of the sterilized by autoclaving 6 times for 2 hours at 120oC (2 atmospheres, or 2 kg/cm2) each time of autoclaving for 10 days soil with high content of organics (12%) [41].

RESULTS

The ET frequency as we have counted the newly grown recombinant mushrooms was about 6.5 x 104 transformants per each microgram of the recombinant DNA isolated from E. coli cells to which it has been electrrotransformed before when we have added the “aaaaa” spacers into the potatoes DNA. Again, the growth of the electrotransormants has happened in the sterile Corporate facility where we have set the sterile boxes with the high in organic content soil. After the electrotranformants were grown, their spores were maintained under the regular non-sterile conditions. So, the recombinant mushrooms which have contained the recombinant potato genes for the testing purposes were grown under normal non-sterile conditions at the corporate facility.

DISCUSSION

Our ultimate success with the genetically engineered recombinant potatoes concerning any vegetable products to be expressed in the white tubular mushroom of family Borovik has led us to the desire to publish more of separate articles like this one describing our experiences with other recombinant vegetables created like this one. We were correct anticipating that in the foods we have prepared per the recommendations published at [XX] the taste of the recombinant potato was almost similar to the taste of real potatoes. Our anticipations that the recombinant potato in the recombinant mushrooms cooked to make soups or fry them to make the fried potatoes [XX] looked and tasted like the very same boiled in soup or fried potatoes [XX]. With the recombinant potato we have prepared the potato salad using the boiled precombinant potato. The taste was delicious as we and our Senior Executives team of our corporations (the testers) admitted and asked for more of such recombinant food to eat despite the Author has advised them that this recombinant potato has not been recommended by the FDA for consumption as of yet. The tasters were the Author himself and the Senior Executives of the Corporations the Author owns. They all stated that the recombinant foods were just like the real boiled or fried potatoes in their taste in the dishes we have cooked for our the Senior Executive team of our Corporations aimed to taste and spread the received knowledge of the genetically engineered vegetables among our valued customers to get ready for the mass production and related to that mass consumption of the boiled or fried vegetables for our valuable customers after the Governmental approval (FDA) of our genetically engineered foods. We did not expand our tasting experience above that since the dishes were eaten completely by the Senior Executives of our corporations and the Author himself despite of his warning to all testers. None of the Senior Executives of our corporations had any digestion disturbance after having said cooked Carbon Negative genetically engineered foods at our corporate site. No any outstanding health effect or side health reactions were observed by anyone who tasted the cooked genetically engineered vegetables. Everyone was really happy and wanted more of said foods whenever that was possible. As we have promised above we are ready to cope with the associated with the coming in the next 10-25 years shortness of the fresh water on our planet and related to that circumstance shortness of the manufacture of livestock, crops and any foods. We are ready to manufacture enough genetically engineered foods after its approval by the FDA using our described herein strategy of using the Carbon Negative white tubular mushrooms where we will introduce the recombinant genes from recombinant meats, vegetables, spices, bread-like structures and beans. Other genetically engineered foods will also be produced but currently we do not have any idea on that kind of foods the customers would like to get at our new type of gas stations [42-44], shown below in Figure 1.The question still exists how we would cope with the fresh water shortness for body washing and laundry purposes: we have to produce the abundant amount of distilled water for doing laundry and washing the bodies of our valued customers and sell it for a very low price. This topic is still in discussions around our corporate top Executive Management and we will publish that topic also as soon as we will get the economically sound solutions for this problem. Another topic comes out from our description of the genetically engineered vegetables production at our corporations. This is extremely important as it has to be done for any sort of Carbon Negative genetically engineered foods we will produce. The authorization of the Governmental authorities is needed to use stated herein kinds of all the genetically engineered foods we will produce at our corporations fro our valued customers.

ECLARATION OF INTERESTS STATEMENT

Ethics approval and consent to participate

The Author has received all the proper documents granting the Ethical Approval and the Consent to Participate from the State of Texas officials. The Author has made sure that the ethical approval and his consent to participate in preparation and submission for publication of this article were properly approved by the respective authorities of the State of Texas.

Consent for publication

The Author has expressed his complete consent to participate in work with this article and its publication in this Journal.

Availability of data and materials

The Author makes all his data and materials herein available for any third party. The data and materials might be obtained from the Author at PO Box 300230, Houston, TX, 77340. Email professordrmichaelvtyurin@gmail.com. If any third party needs any materials used to publish this article, please, do contact the Author.

Competing interests

This article is another the Author’s move in the war which has started by SHELL International Petroleum Corporation some time back by attempted murder of the Author. The people hired by SHELL has totalled the Author’s corporate car and did some other illegal things to the Author which have concluded the Author that the war with the international petroleum corporations has started already. No Houston FBI or Houston Police investigation of said attempted murder has happened and this is behind the responsibility of the Texas Governor with all the legal remedies the Author might use in his fight to sue the State and its Governor Gregory Abbott. The attempted murder has the statute of limitations 20 years, and there are jurisdictions above the level of the State of TEXAS. The Author had certain legal problems with the at that time Attorney General of the State of Texas in 2013, now Texas Governor, Greg Abbott and the Author is going to resolve all the legal problems with the Texas Governor, regardless would he be dismissed or not. The corporate Author’s website http://syngasbiofuelsenergy.com was destroyed by the person, the Attorney of Hirsch and Westheimer Law Firm, PC by the last name Levy. She belongs to the same family which owned or owns the grocery stores chain named “Fiesta” in Houston Texas. The Author was unable to find a lawyer in Texas to file the respective federal law suit and recover his corporate website, but the Author has the US Constitutional right to recite this website in the references herein. Therefore, the Author has multiple legal problems with the State of Texas and the Author is going to resolve said legal problems at the respective Court level in the US. The Author is already involved into the war which has been started by the International Petroleum Corporation SHELL. The Author has approached SHELL offering them for the commercialization the proprietary technology of Gasoline or Diesel fuel manufacture from the air CO2 , not from petroleum which SHELL and other international petroleum corporations use. SHELL representative met the Author, got his draft of the at that time in publication article on creation Gasoline from the air CO2 [1-29]. Then SHELL hired two Mexicans to kill Dr. The Author in the car accident, paying the possibly around $6,000 for this dirty job, which has been done in Houston TEXAS at the US59 down South (9494 Southwest Fwy). The Houston FBI and the Houston Police were contacted by the Author multiple times over his mobile phone however there was no any detailed and thorough Police or the FBI investigation of said attempted murder of the Author since as the Author trusts, both Houston FBI and Houston Police are totally corrupted by the international petroleum corporations. Therefore, any law is not used in the State of Texas to hurt said corporations. Therefore, the Author has to look for the law enforcement outside of the State of Texas, at the National level and he will do that to affect the Texas Governor Abbott for his actions of 2013 and have him resign from his position. Therefore, the Author has conflict of interests with the State of Texas, TEXAS Governor Gregg Abbott, Texas FBI and Texas Police. Since that time more scientific publications of the Author on the Gasoline and Diesel fuel production from the air CO2 came out [20-55]. The US patents are extremely expensive; therefore, the Author uses instead of patents scientific publications. Publications are as good as the US patents, each the US patent has to claim something better than the Author already did in his scientific publications. The Author working on the Acetogens-biocatalysts has no any competition in the world because of his prior invention, the electroporation / electrofusion Generator, already sold as a sample (with no right for reproduction) to the US corporation BTX, Inc. / Genetronics, Inc. (San-Diego, CA). Said Generator and the invented by the Author genome tailoring technology make him proud to be with no any competition in the whole World. Mentioning of names Dr. Gak, Dr. Kiriukhin, Dr. Padda in certain publications herein and elsewhere.

REFERENCES

- Tyurin MV .Carbon Negative Genetically Engineered Foods for Humankind. Submitted for publishing to Food Science and Technology. 2023.

- Tyurin MV. Carbon Negative Genetically Engineered Foods for Humankind. Int J Res Appl Sci Eng Technol. 2023.

- Tyurin MV. Clouds and Rains Caused by Evaporation of Fresh Water from Mexican Gulf and Gulf of California. Int J Dev Res. 2024.

- Tyurin MV. The Market Size for Carbon Negative Replacements of Gasoline and Diesel Fuel and the Manufacture of the Carbon Negative Mixtures. J Med Res Health Sci. 2023; 12: 934-955.

- Tyurin MV. New Carbon Negative Mixes Comprising 1,1-Dibutoxybutane. Int J Analyt Bioanal Techniques. 2023.

- Tyurin MV. Carbon Negative Mixes Comprising 1,1-Dibutoxybutane. Int J Res Appl Sci Engineering Technol Int. 2023; 11: 839-846.

- Tyurin MV. Sea Water Distillation as the Way to Fight Fresh Water Loss to the Outer Space. Water. 2023; 15: 838-949.

- Tyurin MV. Carbon Negative Gasoline and Diesel Fuels replacements. 2023.

- Tyurin MV. Industrial Use of Products from Acetogens. 2023; 1-26.

- Tyurin MV. Inexpensive Resolution of Global Environmental Problem. 2023; 1-29.

- Tyurin MV. Carbon Negative Replacements of Gasoline and Diesel fuel. 2023; 1-31.

- 12. Tyurin MV. Carbon Negative Gasoline and Diesel Fuel Replacements. Clin Med Insights. 2023; 396-414.

- Tyurin MV. 2007.

- Liping Zeng, Qiang Zhang, Renran Sun, Hongzhi Kong, Ning Zhang, Hong Ma, et al. Resolution of deep angiosperm phylogeny using conserved nuclear genes and estimates of early divergence times. Nat Commun. 2014; 5: 4956.

- Tyurin MV. Electrotransformation of Boletus edulis. J Diabetes Res Rev Reports. 2024; 2: 1-7.

- Machida-Hirano R. Diversity of potato genetic resources. Breed Sci. 2015; 65: 26-40.

- Hawkes JG, Jackson MT. Taxonomic and evolutionary implications of the Endosperm Balance Number hypothesis in potatoes. Theor Appl Genet. 1992; 84: 180-185.

- Hijimans RJ, Spooner DM. Geographic distribution of wild potato species. Am J Bot. 2001; 88: 2101-2112.

- Machida-Hirano R. Diversity of potato genetic resources. Breed Sci. 2025; 65: 26-40.

- Iwanaga M, Peloquin SJ. Origin and evolution of cultivated tetraploid potatoes via 2n gametes. Theor Appl Genet. 1982; 61: 161-169.

- Watanabe KN, Peloquin SJ. Occurrence of 2n pollen and ps gene frequencies in cultivated groups and their related wild species in tuber-bearing Solanums. Theor Appl Genet. 1989; 78: 329-336.

- Watanabe KN, Peloquin SJ. The occurrence and frequency of 2n pollen in 2x, 4x, and 6x wild, tuber-bearing Solanum species from Mexico, and Central and South America. Theor Appl Genet. 1991; 82: 621-626.

- Watanabe KN, Peloquin SJ, Endo M. Genetic significance of mode of polyploidization: somatic doubling or 2n gametes? Genome. 1991; 34: 28–34.

- Watanabe KN. Potato genetics, genomics, and applications. Breed Sci. 2015; 65: 53-68.

- Halterman D, Guenthner J, Collinge S, Butler N, Douches D. Biotech potatoes in the 21st century: 20 years since the first biotech potato. Am J Potato Res. 2015; 93: 1-20.

- Hameed A, Zaidi SS-E-A, Shakir S, Mansoor S. Applications of new breeding technologies for potato improvement. Frontiers Plant Sci. 2018: 9.

- The Potato Crop. Its Agricultural, Nutritional and Social Contribution to Humankind. 2020.

- Tyurin MV. Expression in situ of the recombinant human erythropoetin and recombinant insulin. Abstr Webinar on Managing Chronic Conditions in Diabetic and Obese Patients with Remote Patient Monitoring. Colorado, Denver. 2022.

- Tyurin MV. Russian Patent RU 2-005776-2. Plate-parallel polished electrodes and the process of their manufacture from the titanium- based metal alloy VK-2. 1992.

- Tyurin MV. Russian Patent RU 2-005776. Generator for electrotransformation and electrofusion/electrodistruction of various cells: microbial, animal, plant and the process of its manufacture, and the set of plate-parallel polished electrodes and the process of their manufacture from the titanium-based metal alloy VK-2. 1992.

- Solanum melongena DNA, scaffold: Sme2.5_00002.1, whole genome shotgun sequence

- Sauquet H, Magallón S. Key questions and challenges in angiosperm macroevolution. New Phytologist. 2018; 219: 1170-1187.

- Chase M. An update of the Angiosperm Phylogeny Group classification for the orders and families of flowering plants: APG IV. Botanical J Linn Soc. 2016; 181: 1-20.

- Jinhui Chen, Zhaodong Hao, Xuanmin Guang, Chenxi Zhao, Pengkai Wang, Liangjiao Xue, et al. Liriodendron genome sheds light on angiosperm phylogeny and species–pair differentiation. Nat Plants. 2018; 5: 18-25.

- 35. Shu-Miaw Chaw, Yu-Ching Liu, Yu-Wei Wu, Han-Yu Wang, Chan- Yi Ivy Lin, Chung-Shien Wu, et al. Stout camphor tree genome fills gaps in understanding of flowering plant genome evolution. Nat Plants. 2019; 5: 63-73.

- Tyurin MV. New type of Gas stations. Submitted to Applied Sciences. 2014.

- Tyurin MV. Expression in situ of the recombinant human erythropoetin and recombinant insulin. 2022.

- Tyurin MV. Expression in situ of the recombinant human erythropoetin and recombinant insulin. Abstrt of the 2nd Global Meeting on Diabetes and Endocrinology. 2022.

- Tyurin MV, Padda RS. Nitrogen gas reducing commercial acetogen biocatalyst suitable for direct and selective reduction of CO2 inorganic carbon to organic carbon and atmospheric nitrogen to fuel isobutanol during continuous fermentation of CO2 + H2 + N2 gas blend. Int Res J Appl Sci Engineering Technol. 2019; 4: 1-10.

- Tyurin MV, Padda R, Huang KX, Wardwell S, Caprette D, Bennett GN. Electrotransformation of Clostridium acetobutylicum ATCC 824 using high-voltage radio frequency modulated square pulses. J Appl Microbiol. 2000; 88: 220-227

- Kiriukhin M, Tyurin MV, Gak E. UV-induced mutagenesis in acetogens: resistance to methanol, ethanol, acetone, or n-butanol in recombinants with reduced genomes during continuous CO2 / H2 gas blend fermentation. World J Microbiol Biotechnol. 2014; 30: 1559-1574.

- Vel Berzin, Kiriukhin M, Tyurin M. Elimination of acetate production to improve ethanol yield during continuous synthesis gas fermentation by engineered biocatalyst Clostridium sp. MTEtOH550. Appl Biochem Biotechnol. 2012; 167: 338-347.

- Berzin V, Tyurin M. Acetogen biocatalyst Clostridium sp. MTEtOH871 engineered with our proprietary electrotransformation technology and equipment: continuous synthesis gas fermentation for selective ethanol production. J Biotech Res. 2012; 4: 54-64;

- Berzin V, Kiriukhin M, Tyurin M. “Curing” of plasmid DNA in acetogen using microwave or applying an electric pulse improves cell growth and metabolite production as compared to the plasmid-harboring strain. Arch Microbiol. 2013; 195: 181-188;

- Berzin V, Kiriukhin M, Tyurin M. Selective n-butanol production by Clostridium sp. MTButOH1365 during continuous synthesis gasfermentation due to expression of synthetic thiolase, 3-hydroxy butyryl-CoA dehydrogenase, crotonase, butyryl-CoA dehydrogenase, butyraldehyde dehydrogenase and NAD-dependent butanol dehydrogenase. Appl Biochem Biotechnol. 2013; 169: 950-959.

- Berzin V, Kiriukhin M, Tyurin M. Cre-lox66/lox71-based elimination of phosphotransacetylase or acetaldehyde dehydrogenase shifted carbon flux in acetogen rendering selective overproduction of ethanol or acetate. Appl Biochem Biotechnol. 2013; 195: 181-188.

- Tyurin M, Kiryukhin M, Berzin V. Electrofusion of untreated cells of the newly isolated acetogen Clostridium sp. MT351 with integrated in the chromosome erm(B) or cat leading to the combined presence of these antibiotic resistance genes in the chromosome of the electrofusion products. J Biotech Res. 2012; 4: 1-12.

- Tyurin M, Kiriukhin M. Expression of amplified synthetic ethanol pathway integrated using Tn7-tool and powered at the expense of eliminated pta, ack, spo0A and spo0J during continuous syngas or CO2 /H2 blend fermentation. J Appl Microbiol. 2013; 114: 1033-1045.

- Berzin V, Kiriukhin M, Tyurin MV. Selective production of Acetone during continuous synthesis gas fermentation by engineered biocatalyst Clostridium sp. MAceT113. Letters of Appl Microbiol. 2012; 55: 149-154. .

- Tyurin MV, Kiriukhin M. Selective methanol or formate production during continuous CO2 fermentation by the acetogen biocatalysts engineered via integration of synthetic pathways using Tn7-tool. World J Microbiol Biotechnol. 2013; 29: 1611-1623.

- Tyurin MV, Kiriukhin M. 2,3-Butanediol production by engineered acetogen biocatalyst during continuous fermentation of syngas or CO2/H2 blend. Appl Biochem Biotechnol. 2013; 170: 1503-1524.

- Kiriukhin M, Tyurin MV, Gak E. UV-induced mutagenesis in acetogens: resistance to methanol, ethanol, acetone, or n-butanol in recombinants with reduced genomes during continuous CO2 / H2 gas blend fermentation. World J Microbiol Biotechnol. 2014; 30: 1559-1574.

- Kiriukhin M, Tyurin MV. Mevalonate production by engineered acetogen biocatalyst during continuous fermentation of syngas or CO2/H2 blend. Bioprocess Biosyst Eng. 2014; 37: 245-260.

- Kiriukhin M, Tyurin MV. Mevalonate production by engineered acetogen biocatalyst during continuous fermentation of syngas or CO2/H2 blend. Bioprocess Biosyst Eng. 2014; 37: 245-260.

- Gak E, Tyurin MV, Kiriukhin M. Genome tailoring powered production of isobutanol in continuous CO2 / H2 blend fermentation using engineered acetogen biocatalyst. J Ind Microbiol Biotechnol. 2024; 41: 763-781.