Performance Evaluation of Single-Axis Force Gauge in Estimating Cart Turning Exerted Hand Forces

- 1. Spine Research Institute, The Ohio State University, USA

- 2. Department of Integrated Systems Engineering, The Ohio State University, USA

Citation

Harris HL, Weston EB, Marras WS (2025) Performance Evaluation of Single-Axis Force Gauge in Estimating Cart Turning Exerted Hand Forces. JSM Physical Med Rehabil 8(1): 1022

INTRODUCTION

The leading cause of injuries eligible for worker’s compensation among American employees is manual materials handling tasks [1]. Eighty percent of these injuries are classified as low back injuries [1]. Work related physical exposures have been studied extensively in the context of low back pain (LBP). Due to the well studied LBP risk associated with lifting and lowering tasks [2-5], ergonomists have restructured job duties to instead promote pushing and pulling activities [6]. However, pushing and pulling may also contribute to low back injuries. It has been reported that about 10% of costs due to low back disorders in the state of Ohio were related to pushing and pulling tasks [7], and that increased spinal loads can occur during pushing/pulling exertions [8-11]. Thus, there is a need to monitor occupational push-pull exposures.

To estimate musculoskeletal disorder (MSD) injury risk associated with pushing and pulling tasks, ergonomists often measure push/pull forces in the workplace and compare these forces to established guidelines and force limits [12,7]. Thus, obtaining accurate force measurements is crucial to properly assess occupational injury risk.

Three-dimensional (3D) hand transducers are considered the “gold standard” for force measurement but are mostly used in laboratory settings. Instead, a handheld single axis force gauge is often used to measure pushing, pulling, and turning forces in the field due to its portability and relatively low cost in the field. A recent study explored the accuracy and precision of a single-axis force gauge for cart pushing, pulling, and turning exertions [13]. The study found that the resultant push/pull forces derived from a handheld single-axis force gauge agreed well with forces measured by the 3D hand transducer, but there was a significant discrepancy between measured forces of a natural exertion (hands in contact with the 3D load cell) compared to those measured when replicating the natural exertion using the single-axis force gauge. This finding is concerning in terms of injury risk, as inaccurate force gauge readings could result in inaccurate injury risk estimates. The authors were able to adjust for the difference in push/pull forces by recommending that straight push/pull exertions be tested at faster initial and sustained velocities. However, no such adjustment was available for turning exertions, and no other groups have provided guidelines for using a single-axis force gauge to measure hand forces associated with turning exertions.

Addressing this void in ergonomic assessment is crucial, as several prior applied ergonomics studies have found increased biomechanical risk associated with turning exertions. For instance, several studies have found that turning exertions exhibited higher spinal compression and A/P shear loading than those for straight pushing maneuvers [11, 14,15], conducted a study to assess spine loads during patient handling tasks and reported that turning a patient bed around a corner resulted in the highest spinal loads of any maneuver tested, including pushing the bed up a ramp. Another study exploring spine loading in patient handling maneuvers found increased A/P shear in the low back and increased muscle coactivation during turning exertions [10]. Thus, monitoring occupational turning exposures is also essential to a comprehensive ergonomic risk assessment.

Weston [7], developed guidelines and risk limits for pushing and pulling exertions, which determine the percentage of the employee population protected from low back injury. Notably, these guidelines are among the first push/pull guidelines to include recommended limits for turning exertions. However, these guidelines require accurate and precise estimation of natural exerted hand forces during pushing, pulling, and turning exertions to assess injury risk correctly. While adjustments are available when using a single-axis force gauge to measure natural pushing and pulling exerted hand forces [13], no such adjustments are available when using the device to measure natural turning exerted hand forces. Thus, the objective of this study was to explore the accuracy of a single-axis force gauge in measuring exerted hand forces associated with natural turning exertions.

METHODS

Approach

The experimental task involved turning a cart 90° from a standstill along a narrow trajectory. Four measurement schemes were investigated in this study. Subjects first completed turns using the natural scheme, which involved completing 90° two-handed turns with one hand on each cart handle. After force readings were completed using the natural scheme, subjects then completed 90° turns using a single-axis force gauge. Three schemes were tested using the gauge and its compatible attachments. The dependent variables for this study were the accuracy and precision of peak turning exerted hand force magnitude and angle of force application at the peak turning exerted hand force for the natural and gauge schemes.

Subjects

Nine subjects (8 male, 1 female) age 22.3 ± 2.8 (SD) years participated in this study. Eight subjects were unfamiliar with force assessments and using a force gauge. One subject was familiar with force assessments and using a force gauge. Subjects provided informed consent to the research protocol as approved by the University’s Institutional Review Board.

Experimental Design: This study implemented a balanced 4x3x2 experimental design. Four schemes, three handle heights, and two cart weights were recorded with three repetitions, resulting in 72 trials per subject.

Independent Variables: Independent variables for this study included scheme, handle height, and cart weight. The four schemes tested are described in Table 1. The two pushing schemes were either timed or untimed. When untimed, subjects were asked to subjectively recall and match the natural turn as best as possible; in contrast, when timed, subjects were asked to complete the turn in five seconds with the assistance of a metronome beeping once per second. Pilot testing for the study showed that this time constraint was representative of the time required to complete the natural turns. One untimed pulling scheme was also tested. Handle heights included 32, 40, and 48 in. (81.3, 101.6, and 121.9 cm), which match those available in the push/pull guidelines presented by Weston et al., and are representative of a field surveillance database collected by the research group. Finally, the weight of the cart was adjusted to either 1500 lbs. (680.4 kg) or 2000 lbs. (907.2 kg). Cart weights were chosen based on common targets reported by a partner company when selecting cart and caster pairs for manual materials handling.

Dependent Variables: Dependent measures for this study included the accuracy and precision of peak turning exerted hand force magnitude (recorded from 3D hand transducers and single-axis force gauge) and angle of force application at the peak turning exerted hand force (calculated using trigonometry and force components).

Instrumentation and Apparatus

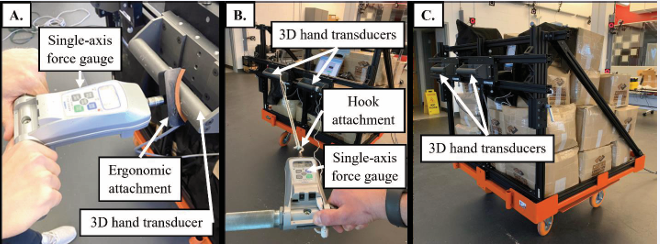

Two instruments were used to collect exerted hand force measurements. All trials recorded exerted hand force measurements using two 3D hand transducers (Bertec HT0825, Worthington, OH, USA), sampling data at 1000 Hz. The 3D hand transducers were considered the “gold standard” of exerted hand force measurement. The cart used in this study allowed for the 3D hand transducers to be imbedded into the cart handles to measure exerted hand forces. Trials using a force gauge scheme also measured exerted hand forces with a single-axis force gauge (Shimpo FGV-500HXY, Cedarhurst, NY, USA) at a sampling frequency of 12.3 Hz. A rounded, padded ergonomic attachment (Shimpo ERGO-KIT, Cedarhurst, NY, USA) compatible with the force gauge was used for the pushing gauge scheme trials (Figure 1A). A hook attachment (included standard with the gauge) was used for the pulling gauge scheme trials (Figure 1B).

The cart used in this study is shown in Figure 1C. The cart itself (CarryMore Tugger Cart System, East Peoria, IL, USA) is dimensioned 127 cm (50 in.) in width and 127 cm (50 in.) in depth, with a mass of 113.4 kg (250 lbs.). It was outfitted with two swivel casters and two rigid casters, all of 20.3-cm (8-in.) diameter (Caster Connection, Columbus, OH, USA). The experimental setup also included a custom T-slotted aluminum frame (80/20 Inc., Columbia City, IN, USA) affixed to the cart that housed the 3D hand transducers. To achieve the handle heights and cart weights tested, the frame was height-adjustable and weighted boxes were added and removed from the cart.

Experimental Procedure

Upon arrival to the laboratory, the researchers described the study objective and experimental task to the potential subjects. Subjects had the opportunity to ask questions and provided consent to participate in the study. Then, subjects were allowed to practice the experimental task before collecting data.

Once ready, the natural scheme trials were collected first. During these trials, subjects were instructed to turn the cart 90° from a standstill with one hand on each 3D hand transducer. There was no linear translation associated with the maneuver; subjects only turned (i.e., spun) the cart 90° in a counterclockwise direction. Data were collected for each combination of handle height and cart weight for three repetitions, resulting in 18 natural scheme trials. Researchers reset the cart after each turn to mitigate fatigue effects and properly position the cart casters. The cart casters were positioned parallel with each other and with the sagittal plane of the subject, which provided the “worst case” to initiate the turn.

After completing the natural turns, subjects took a short break. During this time, they were shown how to use the single-axis force gauge with each of the attachments. Subjects were allowed to complete practice turns using each gauge attachment before collecting data. Next, force gauge trials were collected. In these trials, subjects completed the same 90° turn as the natural trials, but this time with the single-axis force gauge in hand. Three force gauge schemes were tested, which involved pushing and pulling with different gauge attachments (Table 1,Figure 1)

Table 1: Descriptions of the four schemes tested in the study.

|

Scheme |

Description |

|

Natural |

Subjects turned the cart 90° from a standstill with one hand on each 3D hand transducer. No force gauge used. |

|

Force Gauge - Pulling |

Subjects recalled and matched natural scheme to the best of their ability using the force gauge by pulling the hook attachment with a rope wrapped around one 3D hand transducer. |

|

Force Gauge - Pushing |

Subjects recalled and matched natural scheme to the best of their ability using the force gauge by pushing the padded ergonomic attachment directly on one 3D hand transducer. |

|

Force Gauge - Timed Pushing |

Subjects were asked to complete the turn in 5 seconds with the assistance of a metronome. Subjects pushed the padded ergonomic attachment directly on one 3D hand transducer to turn the cart. |

Figure 1 : (A) A padded ergonomic attachment for the single-axis force gauge, pushing directly on the 3D hand transducer. (B) A hook attachment for the single-axis force gauge used with a rope, pulling on the 3D hand transducer. (C) Cart outfitted with 3D hand transducers

Data were collected for each combination of force gauge scheme, handle height, and cart weight for three repetitions, resulting in 54 force gauge scheme trials. As previously described, researchers reset the cart after each turn to reduce fatigue effects and properly position the cart casters

Regarding the trial order, natural trials were always collected prior to single-axis force gauge trials. Trials were further blocked on cart weight and collected as either light-heavy-light or heavy-light-heavy to reduce the number of times the weight (500 lbs.) needed to be added or removed from the cart. Finally, within each cart weight block, handle height and force gauge scheme were randomized. Repetitions of each condition were recorded consecutively.

Signal Processing and Statistical Analysis

A fourth-order Butterworth, low-pass filter with a cut off frequency of 10 Hz was applied to the force readings using both technologies. The hand transducer force readings were downsampled to a 12.3-Hz frequency matching that of the single-axis force gauge. Exerted hand force measurements recorded by the hand transducers were also time-synchronized with the force gauge measurements where appropriate using a time delay function in MATLAB (Mathworks, Inc., Natick, MA, USA) that maximized the correlation between the data for each technology.

Resultant natural turning exerted hand forces were calculated using the total magnitude of exerted hand force from each of the 3D force components at each time point per trial. Single-axis force gauge turning exerted hand forces were reported as peak measurements per trial. Angle of force application was calculated using the arctangent of the sum of force components in the horizontal (i.e., parallel to hand transducer) and normal (i.e., perpendicular to hand transducer and vertical axis) directions at the peak resultant exerted hand force (Figure 2).

Figure 2 : Angle of force application diagram. The arctangent of the sums of horizontal (X) forces and sums of normal (Z) forces were used to calculate resultant angle of force application.

Absolute values of the angles were used for statistical analysis. Peak turning exerted hand forces and angles of force application at the peak resultant exerted hand force per trial were extracted to provide averages and standard deviations. Statistical analysis was performed using the JMP Pro 15.2.0 software package (SAS Institute, Inc., Cary, NC, USA), with independent variables analyzed as nominal variables and dependent variables analyzed as continuous variables. Average peak exerted hand force readings from the hand transducers and force gauge for each combination of scheme, handle height, and cart weight were calculated. Percent error for each force gauge scheme was calculated using the natural turning scheme as the reference measurement. Percent error was determined using force readings averaged across subjects for each combination of handle height, cart weight, and scheme. The maximum percent error of all handle heights and cart weights was used to determine correction factors for each scheme (described later).

Agreement measures were evaluated in Microsoft Excel (Microsoft Corporation, Redmond, WA, USA) using intraclass correlation coefficients (ICCs) to determine agreement between the four schemes. The ICC deemed appropriate for this study was ICC(2,k), consisting of absolute agreement, two-way random effects models rating the average of three readings per condition [16]. Since ergonomists often use multiple force readings in risk assessments, using the average of three readings per condition was deemed appropriate for the measures presented herein. Pair-wise comparisons were used to determine ICC point estimates and their respective 95% confidence intervals and ratings between the force readings recorded for each scheme. Agreement ratings were also classified as poor (ICC0.90), as recommended by Koo and Li.

RESULTS

Peak Turning Exerted Hand Force Magnitude

Peak turning exerted hand force magnitude averages, standard deviations, and percent error of the force gauge relative to the natural scheme are listed in Table 2.

Table 2: Average unadjusted turning exerted hand force magnitudes, standard deviations, and percent error of gauge relative to natural scheme per scheme, handle height, and cart weight.

|

Condition |

Scheme |

Average Turning Exerted Hand Force Magnitude (N) |

Turning Exerted Hand Force Standard Deviation (N) |

Error Relative to Natural Exerted Hand Forces (%) |

|

Handle Height |

|

|

|

|

|

32 in |

Natural |

362 |

81.2 |

|

|

Force Gauge (Pull) |

268.9 |

34.6 |

25.7 |

|

|

Force Gauge (Push) |

215.5 |

38.2 |

40.5 |

|

|

Force Gauge (Timed Push) |

231 |

44.7 |

36.2 |

|

|

40 in |

Natural |

310.1 |

82.9 |

|

|

Force Gauge (Pull) |

270.7 |

46.8 |

12.7 |

|

|

Force Gauge (Push) |

213.7 |

46.2 |

31.1 |

|

|

Force Gauge (Timed Push) |

222.3 |

40.4 |

28.3 |

|

|

48 in |

Natural |

316.7 |

77.2 |

|

|

Force Gauge (Pull) |

272.4 |

48.1 |

14 |

|

|

Force Gauge (Push) |

203.8 |

33.1 |

35.6 |

|

|

Force Gauge (Timed Push) |

219.6 |

36.8 |

30.6 |

|

|

Cart Weight |

|

|

|

|

|

1500 lbs. |

Natural |

319.2 |

83.3 |

|

|

Force Gauge (Pull) |

242.8 |

36.2 |

23.9 |

|

|

Force Gauge (Push) |

190 |

33.6 |

40.5 |

|

|

Force Gauge (Timed Push) |

208.2 |

38.9 |

34.8 |

|

|

2000 lbs. |

Natural |

340 |

76.4 |

|

|

Force Gauge (Pull) |

301.2 |

53.4 |

11.4 |

|

|

Force Gauge (Push) |

232.4 |

41.9 |

31.6 |

|

|

Force Gauge (Timed Push) |

241.9 |

42.9 |

28.9 |

|

The average peak turning exerted hand force magnitudes reported for the natural scheme exceeded those reported for all gauge schemes at all test conditions. Natural exerted hand force measurements were less precise (in terms of standard deviation) than any of the force gauge schemes at all test conditions, which suggests that natural turning exertions are not easily repeatable, possibly due to considerable variation in exerted hand forces between subjects.

In contrast, all force gauge schemes underestimated turning exerted hand forces relative to the natural scheme readings. Across subjects and test conditions, the pulling scheme best approximated natural turning exerted hand forces, with an average underestimation of 59.7 N (13.4 lbf), representing a 18.1% error relative to natural exerted hand forces. In contrast, the untimed pushing scheme was the least accurate, underestimating natural turning exerted hand forces by 118.9 N (26.7 lbf), representing a 36.1% error, on average across subjects and test conditions. Generally, the force gauge schemes offer high repeatability but diminished accuracy in measuring natural turning exerted hand forces, which is concerning in terms of risk assessment.

Angle of Force Application at Peak Turning Exerted Hand Force

Table 3

Table 3: Average angle of force application and standard deviations per scheme, handle height, and cart weight.

|

Condition |

Scheme |

Average Angle of Force Application (deg) |

Angle of Force Application Standard Deviation (deg) |

|

|

Handle Height |

|

|

|

|

|

32 in |

Natural |

54.8 |

22.4 |

|

|

|

Force Gauge (Pull) |

47.4 |

24.4 |

|

|

|

Force Gauge (Push) |

15.1 |

4.79 |

|

|

|

Force Gauge (Timed Push) |

15.1 |

3.96 |

|

|

40 in |

Natural |

63.2 |

21.5 |

|

|

|

Force Gauge (Pull) |

67.1 |

14.4 |

|

|

|

Force Gauge (Push) |

16.0 |

4.08 |

|

|

|

Force Gauge (Timed Push) |

15.5 |

4.59 |

|

|

48 in |

Natural |

63.0 |

21.3 |

|

|

|

Force Gauge (Pull) |

64.6 |

16.3 |

|

|

|

Force Gauge (Push) |

14.9 |

4.10 |

|

|

|

Force Gauge (Timed Push) |

15.2 |

4.50 |

|

|

Cart Weight |

|

|

|

|

|

1500 lbs. |

Natural |

61.4 |

18.9 |

|

|

|

Force Gauge (Pull) |

54.4 |

16.0 |

|

|

|

Force Gauge (Push) |

16.1 |

4.97 |

|

|

|

Force Gauge (Timed Push) |

15.4 |

5.40 |

|

|

2000 lbs. |

Natural |

47.8 |

28.9 |

|

|

|

Force Gauge (Pull) |

65.0 |

14.3 |

|

|

|

Force Gauge (Push) |

14.4 |

3.86 |

|

|

|

Force Gauge (Timed Push) |

15.2 |

3.38 |

reports average angles of force application at the peak turning exerted hand force and standard deviations per scheme, handle height, and cart weight. Angles of force application observed with the natural scheme were greater than those observed with the two pushing gauge schemes at all test conditions. Across subjects and test conditions, angle of force application for the pulling scheme best matched that of the natural scheme, while the angle of force application for the timed pushing scheme was the least accurate relative to the natural scheme. The two pushing schemes reported angles of force application much lower than the natural scheme on average for all test conditions. The pushing schemes were the most precise gauge schemes across study conditions, while the pulling scheme was the least precise gauge scheme across study conditions, suggesting that larger angles of force application compromise repeatability.

Agreement Measures (ICCs) and Correction Factors

Table 4

Table 4: ICC point estimates, 95% confidence intervals (CI), and ratings between the four schemes.

|

|

Unadjusted |

Adjusted |

||||

|

Pair-wise Comparison |

ICC Point Estimate |

95% CI |

Agreement Rating |

ICC Point Estimate |

95% CI |

Agreement Rating |

|

|

|

|

|

|

|

|

|

Natural vs. Force Gauge (Pull) |

0.59 |

0.04-0.80 |

Poor-Good |

0.72 |

0.52-0.84 |

Moderate-Good |

|

Natural vs. Force Gauge (Push) |

0.34 |

0.00-0.67 |

Poor-Moderate |

0.72 |

0.50-0.84 |

Moderate-Good |

|

Natural vs. Force Gauge (Timed Push) |

0.44 |

0.00-0.76 |

Poor-Good |

0.82 |

0.67-0.90 |

Moderate-Excellent |

|

Force Gauge (Pull) vs. Force Gauge (Push) |

0.52 |

0.00-0.80 |

Poor-Good |

0.65 |

0.13-0.83 |

Poor-Good |

|

Force Gauge (Pull) vs. Force Gauge (Timed Push) |

0.60 |

0.00-0.83 |

Poor-Good |

0.67 |

0.17-0.85 |

Poor-Good |

|

Force Gauge (Push) vs. Force Gauge (Timed Push) |

0.91 |

0.79-0.96 |

Good-Excellent |

0.93 |

0.88-0.96 |

Good-Excellent |

details the ICCs between peak resultant exerted hand forces recorded per measurement scheme. Regarding agreement in scheme, unadjusted point estimate agreement ratings between the natural and force gauge schemes ranged from poor to moderate. The single axis force gauge pulling scheme had the best agreement to the natural scheme, with an unadjusted ICC point estimate of 0.59, which is classified as moderate. However, both pushing schemes noted poor agreement with the natural turning condition, with ICC point estimates less than or equal to 0.44. In contrast, the force gauge schemes agreed well with each other, with unadjusted point estimates ranging from moderate to excellent. The schemes with the best unadjusted agreement to each other were the pushing schemes (ICC of 0.91), and those with the worst unadjusted agreement to each other were the pulling and untimed pushing schemes (ICC of 0.52).

To improve the agreement of exerted hand force measurements between the natural and force gauge schemes, correction factors were applied to force gauge readings. Separate percent error and correction factors were calculated for each of the three force gauge schemes.Correction factors were determined based on the maximum percent error observed across test conditions of the gauge scheme force readings relative to the natural scheme force readings. For instance, the maximum percent error of 30% observed for the pulling scheme across subjects, handle heights, and cart weights, resulted in a correction factor of 1.30 for the pulling scheme. Correction factors for pulling, pushing, and timed pushing were calculated as 1.30, 1.44, and 1.37, respectively.

To account for the underestimation of natural turning exerted hand forces when using the single-axis force gauge, force gauge measurements were adjusted by multiplying unadjusted peak turning exerted hand force estimates by the correction factors listed above. The peak exerted hand force readings after adjustment per scheme, handle height, and cart weight are listed in Table 5.

Table 5: Average adjusted turning exerted hand force magnitudes, standard deviations, and percent error of gauge relative to natural scheme per scheme per handle height and cart weight. Natural readings were not adjusted

|

Condition |

Scheme |

Adjusted Average Turning Exerted Hand Force Magnitude (N) |

Turning Exerted Hand Force Standard Deviation (N) |

Error Relative to Natural Forces (%) |

|

Handle Height |

|

|

|

|

|

32 in |

Natural |

362.0 |

81.9 |

|

|

|

Force Gauge (Pull) |

351.2 |

62.4 |

3.00 |

|

|

Force Gauge (Push) |

310.4 |

64.6 |

14.3 |

|

|

Force Gauge (Timed Push) |

316.8 |

62.9 |

12.5 |

|

40 in |

Natural |

310.1 |

82.0 |

|

|

|

Force Gauge (Pull) |

354.1 |

79.6 |

14.2 |

|

|

Force Gauge (Push) |

307.3 |

77.0 |

0.93 |

|

|

Force Gauge (Timed Push) |

305.8 |

63.7 |

1.40 |

|

48 in |

Natural |

316.7 |

78.2 |

|

|

|

Force Gauge (Pull) |

356.3 |

75.9 |

12.5 |

|

|

Force Gauge (Push) |

292.2 |

59.3 |

7.73 |

|

|

Force Gauge (Timed Push) |

300.3 |

60.0 |

5.17 |

|

Cart Weight |

|

|

|

|

|

1500 lbs. |

Natural |

319.2 |

84.2 |

|

|

|

Force Gauge (Pull) |

315.4 |

47.9 |

1.19 |

|

|

Force Gauge (Push) |

271.5 |

56.4 |

14.9 |

|

|

Force Gauge (Timed Push) |

283.7 |

54.5 |

11.1 |

|

2000 lbs. |

Natural |

340.0 |

81.0 |

|

|

|

Force Gauge (Pull) |

392.3 |

71.4 |

15.4 |

|

|

Force Gauge (Push) |

335.0 |

61.2 |

1.47 |

|

|

Force Gauge (Timed Push) |

331.5 |

59.4 |

2.50 |

Multiplying gauge force measurements by correction factors did not set the gauge readings equal to the natural force readings, but it did improve the accuracy of all gauge schemes compared to the natural scheme. On average across all subjects and conditions, the pulling scheme overestimated natural turning exerted hand forces after adjustment by 22.3 N (5.0 lbf), representing a 6.8% error relative to natural exerted hand forces. Both pushing schemes still underestimated natural turning exerted hand forces, but to a lesser degree. The underestimation on average across all subjects and test variables of the timed and untimed pushing schemes after adjustment were reduced to 22.6 N (5.1 lbf) and 26.4 N (5.9 lbf), representing a 6.8% error and 8.0% error, respectively. Across subjects and test conditions, the timed pushing scheme after adjustment was the most precise gauge scheme, with a standard deviation of 27.2 N (6.1 lbf).

The agreement measures previously described were recalculated for the adjusted peak exerted hand force estimates. As shown in Table 4, adjusted point estimate agreement ratings between the natural and force gauge schemes ranged from moderate (ICC of 0.72) to good (ICC of 0.82). The timed pushing gauge scheme had the best agreement to the natural scheme after adjustment, with an adjusted ICC point estimate of 0.82. Likewise, adjusted point estimate agreement ratings between the force gauge schemes ranged from moderate to excellent, with the pushing schemes having the best adjusted agreement to each other (ICC of 0.93), and the pulling and untimed pushing schemes having the worst adjusted agreement to each other (ICC of 0.65).

DISCUSSION

Ergonomists must be able to accurately and precisely measure exerted hand forces required for pushing, pulling, and turning maneuvers to evaluate and reduce injury risk in occupational settings. This study aimed to explore the accuracy of a single-axis force gauge in measuring exerted hand forces associated with natural turning exertions. Turning exerted hand forces estimated with the single axis force gauge had poor to moderate agreement with those of the natural scheme, demonstrating the difficulty in replicating and quantifying a complex, two-handed turn using a single-axis force gauge. This underestimation likely resulted from poor coupling between the force gauge and cart handle, which hindered the subjects’ ability to obtain the same angle of force application as might be seen with natural cart turning using both hands. The authors’ solution was to apply custom correction factors per scheme to improve the accuracy of the force gauge readings, though these correction factors may not apply to other conditions, such as varied cart weights or handle heights.

It was discovered early in the study that viable schemes for turning exerted hand force measurement using a single-axis force gauge were limited. The group found that the single-axis force gauge design is not ideal for turning exerted hand force assessment and would require additional force gauge attachments. The two pushing schemes and one pulling scheme tested implemented commercially available attachments compatible with the force gauge. It should be noted, however, that these force gauge schemes presented their own challenges, such as poor coupling between the force gauge and cart handle during the turning exertion. Unlike straight pushing and pulling exertions where forces are exerted normal to the cart handle, turning exertions require forces to be applied at an angle. The angle of force application depends on the magnitude of force components in the horizontal and normal directions, with larger angles having larger force components in the horizontal direction and smaller angles having larger force components in the normal direction. This concept may illustrate the coupling issues evident with the pushing schemes: subjects may have exerted greater forces in the normal direction to prevent the gauge from slipping off the cart handle, resulting in smaller angles of force application. In contrast, the natural and pulling schemes had improved coupling, which allowed subjects to exert greater forces in the horizontal direction, resulting in larger angles of force application. Unfortunately, this change in force application observed with the pushing schemes due to poor coupling may reduce mechanical advantage in cart turning, which may have contributed to differences in exerted hand force measurement between schemes.

To reduce the underestimation of natural turning exerted hand forces using the single-axis force gauge, correction factors custom to each scheme were applied to the force gauge readings. The maximum percent errors for each scheme relative to the natural scheme, which ranged from 30%-44%, were used to create custom correction factors per scheme. Correction factors were then applied to average readings for each combination of handle height, cart weight, and scheme per subject. Because average readings across subjects for combinations of the test conditions were used to calculate the percent error and correction factors, some force readings after adjustment still underestimated natural turning exerted hand force readings. However, after applying correction factors, agreement point estimates between the natural and force gauge schemes improved, ranging from moderate to good instead of poor to moderate.

Some limitations should be considered when evaluating and implementing the results discussed herein. While the accuracy of the force gauge schemes improved with custom correction factors, the correction factors have not been validated for other conditions, such as varied cart weights and handle heights. One should also note the poor lower bounds of the confidence intervals. According to Koo and Li [16], low agreement estimates could be caused by a limited number of subjects. Therefore, more subjects may have improved the agreement estimates presented herein. Finally, most of the study participants were inexperienced in force assessment procedures and using the force gauge. Because ergonomists are more likely to be experienced in risk assessment and using a force gauge, their participation may have been better suited for the purposes of this study as opposed to mostly novice subjects.

Future research in turning force assessment using a single-axis force gauge should assess the performance of a timed pulling scheme. A timed pulling scheme was not tested in this study to limit the number of trials per subject to mitigate fatigue effects. However, timing the pushing scheme generally produced results more consistent with the natural scheme, which suggests that, in practice, a timed exertion may yield the most reliable results. Thus, the authors recommend future research to assess the accuracy and precision of a single-axis force gauge using a timed pulling scheme to estimate natural turning exerted hand forces.

CONCLUSION

The purpose of this study was to explore the accuracy of a single-axis force gauge in measuring exerted hand forces associated with natural turning exertions. Using a one dimensional tool to measure exerted hand forces during a two-handed turn was a challenge throughout the study. All force gauge schemes tested underestimated natural turning exerted hand forces, yielding poor to moderate point estimate agreement ratings between natural and force gauge schemes. To reduce underestimation and improve accuracy, correction factors custom to each gauge scheme were applied to exerted hand force measurements recorded by the force gauge, but these correction factors are specific to the handle heights and cart weights tested herein. Ultimately, these results suggest a standard test protocol involving a timed exertion and an attachment to improve coupling between the force gauge and the cart handle. Based on the results of this study, it is recommended that turning exerted hand forces be assessed by pushing the cart using an ergonomic attachment on the single-axis gauge that improves coupling and timing the exertion using a metronome, and the force readings should be corrected with a factor of 1.37 to estimate injury risk. Further research should investigate the performance of a single-axis force gauge using a timed pulling scheme to estimate natural turning exerted hand forces.

ACKNOWLEDGEMENTS

This research was partially funded by an NSF Industry/ University Cooperative Research Program called the Center for Disruptive Musculoskeletal Innovations (IIP 1916629). The cart and weighted boxes used in this study were supplied by Caster Connection (Columbus, OH, USA). The authors would also like to acknowledge Dylan Aery and Christopher Haritos for assistance in data collection and W. Gary Allread for assistance in the piloting phase of the study.

REFERENCES

- OSHA. Back Disorders and Injuries. OSHA technical manual (Sec. VII).United States Department of Labor. 2021.

- Coenen P, Kingma I, Boot CR, Twisk JW, Bongers PM, van Dieën JH. Cumulative low back load at work as a risk factor of low back pain: a prospective cohort study. J Occup Rehabil. 1993; 23: 11-18.

- Harkness EF, MacFarlane GJ, Nahit ES, Silman AJ, McBeth, J. Risk factors for new-onset low back pain amongst cohorts of newly employed workers. Rheumatology (Oxford). 2003; 42: 959-968.

- Hoogendoorn WE, Bongers PM, De Vet HC, Douwes M, Koes BW, Miedema MC, et al. Flexion and rotation of the trunk and lifting at work are rissk factors for low back pain: results of a prospective cohort study. Spine (Phila Pa 1976). 2000; 25: 3087-3092.

- Marras WS, Lavendar SA, Leurgans SE, Rajulu SL, Allread WG, Fathallah FA, et al. The role of dynamic three-dimensional trunk motion in occupationally-related low back disorders: The effects of workplace factors, trunk position, & trunk motion characteristics on risk of injury. Spine (Phila Pa 1976). 1993; 18: 617-628.

- Resnick ML, Chaffin DB. An ergonomic evaluation of handle height and load in maximal and submaximal cart pushing. Appl Ergon. 1995; 26: 173-178.

- Weston EB, Alexander A, Jonathan SD, Gregory GK, William SM. Biomechanically determined hand force limits protecting the low back during occupational pushing and pulling tasks. Ergon. 2018; 61: 853-865.

- Jäger M, Sawatzki K, Glitsch U, Ellegast R, Ottersbach HJ, Schaub K, et al. Load on the lumbar spine of flight attendants during pushing and pulling trolleys aboard aircraft. Int J Ind Ergon. 2007; 37: 863-876.

- Knapik GG, Marras WS. Spine loading at different lumbar levels during pushing and pulling. Ergonomics. 2009; 52: 60-70.

- Marras WS, Knapik GG, Ferguson S. Lumbar spine forces during maneuvering of ceiling-based and floor-based patient transfer devices. Ergon. 2009; 52: 384-397.

- Sandfeld J, Rosgaard C, Jensen BR. L4-L5 compression and anterior/ posterior joint shear forces in cabin attendants during the initial push/pull actions of airplane meal carts. Appl Ergon. 2014; 45: 1067- 1075.

- Snook SH, Ciriello VM. The design of manual handling tasks: revised tables of maximum acceptable weights and forces. Ergon. 1991; 34: 853-865.

- Weston EB, Marras WS. Comparison of push/pull force estimates using a single-axis gauge versus a three-dimensional hand transducer. Appl Ergon. 2020; 88: 103184.

- Weston EB, Khan SN, Marras WS. Wheelchair pushing and turning: lumbar spine and shoulder loads and recommended limits. Ergon. 2017; 60: 1754-1765.

- Kotowski SE, Davis KG, Marras WS. Patient handling through moving of the beds and stretchers. Int J Ind Ergon. 2022; 87: 103252.

- Koo TK, Li MY. A guideline of selecting and reporting intraclass correlation coefficients for reliability research. J Chiropr Med. 2016; 15: 155-163.