Can Phase Change Materials Clothing be worn to Avoid Viral Thermal Fever Complications? A Numerical Study

- 1. Department of Physics, LPMMAT Laboratory,Hassan II University of Casablanca, Morocco

Abstract

This paper is concerned about the cooling ability of phase change materials (PCM) cold clothing (uniform suit) wearied to a body subject to thermal viral fever. These PCM integrated cloths perform the action of either absorbing or releasing heat to keep the body in safe thermal conditions. In order to investigate the performances of PCM suit in the control of viral thermal fever evolution, the transient thermal balance, taking into account the sensible energy storage in the body coupled with the melting process within the PCM clothing, is developed using the dynamic two-nodes human body thermoregulation model. The enthalpy method is used for the energy equation in the PCM. The cooling capabilities of six different PCM suits (Tmelt= 14.4, 21, 23, 26.6, 29 and 32°C) were tested for a body suffering from high metabolic rate due to rigorous thermal viral fever with core temperature above 41.1°C. The results showed that the convenient PCM clothing reduces the core temperature from Hyperpyrexia to Moderate grade fever during four hours. When no effective therapy lysis was prescript, the fever intensify to High-grade fever due to the complete melting of the PCMon the following hours nevertheless, the heating effects of fever is lasted about 6 hours. The PCM cloths contribute to deep cooling of the skin and the body rejects more heat than the case of normal suit. Moreover, water loss due to sweating is reduced by about 10 % and 1.5 % during the two first and fifth hours, respectively, compared with the case of normal cloths. Besides, the results showed that the PCM uniform with higher latent heat of fusion had a greater and longer cooling effect giving additional time scheme to prescribe suitable fever therapy.

Keywords

Thermoregulation; Covid 19 fever; PCM suit; Thermal viral fever; Enthalpy method; Metabolic heat; Physiology; Blood rate; Sweating; Shivering; Skin temperature.

CITATION

Faraji M (2020) Can Phase Change Materials Clothing be worn to Avoid Viral Thermal Fever Complications? A Numerical Study. J Fever 3(1): 1010.

ABBREVIATIONS

sensible heat loss from the skin through clothing (W/

)

specific heat (kJ/kg K)

evaporative heat loss from the skin (W/

)

PCM layer thickness (m)

liquid fraction

clothing area factor. The surface area of the clothed body divided by the surface area of the nude body

enthalpy (J)

convective and evaporative respiratory heat loss (W/

)

convective heat transfer coefficient (W/

K)

thermal conductivity (W/m K)

mass (kg)

metabolic heat generation (W/

)

energy production by shivering (W/

)

saturated vapor pressure at air temperature (kPa)

saturated vapor pressure at skin temperature (kPa)

sensible heat stored per square meter cloths (J/m²)

sensible heat stored per square meter cloths (J/m²)

heat of vaporization of waterkJ/ kg

sweat rate (kg/ h)

time (s)

temperature (°C)

mean body temperature (°C)

core temperature (°C)

rectal temperature (°C)

blood flow (l/h)

skin wittedness

Indices

control volume near inner face and outer face

melting PCM

+,- right , left nodes

Fusion

Greeks

density (kg/

)

relative humidity

thermal diffusivity (m²/s)

relative mass of skin to the core

latent heat of PCM (kJ/kg)

INTRODUCTION

Thermo-regulation of clothing consists of the facility of textile material to prevent the body, under dynamic external environment, from an unexpected rise or fall from physiological comfort temperature. Phase change Materials (PCMs) demonstrate the property of thermal buffering by reducing the barrier of moisture [1]. Phase change Materials (PCMs) stores the heat of transformation energy and release the stored heat during the cooling period to ambient [2,3]. Organic PCMs as paraffin absorb 200 kJ/kg of the warmth of transformation during phase transition which is released to the environment during solidification. The temperature of PCMs doesn’t vary significantly during the melting and solidification process. Phase change materials shifts passively the peaks in temperature variations within clothing. In 1980s, National Aeronautics and Space Administration (NASA) USA employed PCMs in smart clothing materials to make thermo-regulated wear for spacecrafts devices to avoid unanticipated change in temperature [4,5]. Outlast Technologies incorporated viscose fibers with PCMs [6]. These PCMs incorporated textiles offer heat rise absorber effect under sudden weather temperature variations by regulating the skin temperature to accepted level and thus providing extended comfort. Also, in cold environment, PCMs can minimize the garment thickness required for the protection of human body from subcooling [5]. Currently, PCMs are applied in various textiles including garb, bedcovers, non-woven, and footwear. the foremost functions that a phase change material (PCM) should to perform when incorporated with a textile substrate are Cooling by heat absorption, Heating by heat release, Thermoregulation resulting in a mix of cooling and heating, An active thermal barrier effect, resulting from either heat absorption, or heat emission of the PCM which regulates the human body heat rate and adopts it to the thermal needs depending to activity level and ambient temperature. PCMs are characterized by their phase change temperature ranges and their heat storage capacities. The required properties for a PCM for a high-efficiency cooling system for a specific application, like in textile fields are: melting point between 14 and 35°C; large heat of fusion; little temperature difference between the melting and thus the solidification point; low toxicity; stability for repetition of melting and solidification; large thermal conductivity; simple availability and low price. Before applying PCMs to textile structure, the PCMs would be encapsulated in very small shells to contain them while during a liquid state. Many scientists, using different techniques, integrate microencapsulated phase change materials (MPCM) into textile fibers. Micro capsules of n-eicosane PCM are integrated into acrylic and viscose fiber using dry/wet rotating technique [7]. These filament wools gave thermo-regulating effect. Viscose and acrylic incorporated with leak resistant capsules were successfully marketed by Outlast Technologies [6]. Hartman alongside his research colleagues [8] within the continuation of his previous work, synthesized viscose fiber incorporated with microencapsulated PCMs with the heat storage capacity within the range of 1 to 20 J/g. Zhang et al. [9] developed poly acrylo nitrile-vinylidene chloride using wet spinning technique, the n-octadecane PCM is encapsulated within urea copolymer. They studied the quantity of integrated MCPM into the fiber. From the convenient spinning process, up to 30% MCPMs are often added. Actually MPCMs are used into textiles to provide temperature control and greater comfort by trapping then releasing stored heat as needed. Wang et al. [10] investigate the impact of phase change materials (PCM) on thermal-protective clothing within the heating process, when the PCM layers temperature increases above the PCMs melting point (28.0°C), the PCM melts and becomes liquid. During this phase change, thermal energy is absorbed and released. In any case the PCM becomes liquid, the temperature continually increases. When the PCM layer temperature reaches 29.0°C, the conductive fabrics were powered off. The temperature of the PCM layer then decreases after a quick time. When liquid PCM becomes solid it releases heat and the temperature of the PCM layer decreases less than 27.0°C. During this process, the PCM acts as a thermal buffer material by releasing stored heat. The electricity consumed by the clothing assembly (nonwoven fabric coated with PCM and having conductive layer) with PCM is about half pf that consumed by the clothing assembly without PCM (nonwoven fabric, having conductive layer). Conductive fabric can significantly increase the temperatures of the various layers of the assembly and make the assembly warmer. Nonwoven protective garments are utilized during the virus pandemic control and the treatment of hazardous waste. Nonwovens utilized in such garments provide a high barrier function against the penetration by dust, liquids, or gases. However, within an equivalent way, the fabric system prevents the transfer of hazardous materials into the garment. It also limits the outward passage of body heat and moisture. As a result, under strenuous activities, the core temperature of the wearer’s body may rise quickly above the comfort level into the stress zone. The matter is typically solved by applying phase transition materials. The incorporation of PCM during a nonwoven fabric system adds a thermo-regulating feature. By using such nonwoven fabric systems with incorporated PCM for protective garments, the wearers comfort are often enhanced substantially and thus the occurrence of heat stress might be prevented [11]. In previous literature research efforts, the authors focus on the thermal comfort of PCM clothing wearers. No work on how can PCM clothing lower the body temperature of febrile subject was done. Applications of PCM in medical and health fields, especially to manage the temperature of febrile subjects, are becoming to be focused within this paper, which has tremendous potential applications of PCM. The physical body could even be a thermo-regulated organism. The healthy body constantly generates heat, CO2 and H2 O by the metabolism of food and muscle activity. The man body controls the discharge speed of heat by vessel dilatation temperature. It’s been shown that the foremost comfortable skin temperature is 31.4°C. When the temperature of any area of the skin differs by within 1.5-3.0 °C of this ideal temperature, the physical body is unaware of the heat or coolness. If the difference is around 4.5°C, the physical body feels discomfort. Additionally, a core body temperature of 36.5°C is required, and an increase or fall of 1.5°C is typically fatal. A balance between the rates of heat loss and generated must be maintained. Various viral inflammations contribute to sever fever generation by activating cold-sensitive cutaneous nerves, which successively, transmit fever signals to parts of the brain liable for fever generation [28]. In sever malaria or in the case of Covid 19 virus contagion, the physiological thermoregulatory of body subject to thermal viral fever become almost slightly a bit like the processes of exposure to cold temperature. Viral attack and synthesis of Pryogensmicro-organisms or products of microorganisms such as toxins and gram negative cells provoke tissue inflammatory and abnormal internal body heat generation. Other fever inflammatory mediators may alter set-point and lead to unregulated rise in body temperature. The prescription of anti-inflammatory exert their anti-pyretic effects by inhibiting synthesis of pyrogenic micro-organisms and increasing heat loss by enhancing sensitivity of warm sensitive neurons protect the host against the destructive consequences of unchecked fever in the preoptic area and then activates thermal neurons in the anterior hypothalamus to a higher thermal balance point [28]. In thermal fever, the thermal balances then the aim temperatures are reset to higher levels just like the core and skin thermoregulatory sensors temperature are abnormally sensed as cold temperatures, and as a result, the blood temperature rises incessantly, depending on nature and severity of viral inflammation [12,13]. Defining febrile body temperatures remain a topic of debate with varied definitions by different authors. However, most authors [14-16] defined fever in healthy adults as a temperature greater than 37.7°C at any time during the day. Supported the principles for the management of febrile illnesses provided by authorities like World Health Organization (WHO) [17,18] and thus the disease Society of America (IDSA) [19,21], equivalent rectal temperature of up to 38°C is indicative of fever. Consistent with [22,23] data, normal and febrile body temperature are defined as: normal body temperature 37-38°C, Mild/low grade fever 38.1-39, Moderate grade fever 39.1-40°C, High-grade fever 40.1-41.1°C, Hyperpyrexia >41.1°C. The study of physiological regulation of temperature in man body could even be an important research field. Stolwijk [24] presented a 25-nodes dynamic mathematical model of physiological regulation of body temperature. These nodes represent the thermal characteristics of the body, with four nodes each representing the head, trunk, arms, hands, legs, and feet. The twenty-fifth node represents the central blood. Stolwijk[24] considered clothing as a simple insulation without mass. The Berkeley Comfort Model [25], based on the Stolwijk model also as on work by Tanabe [26], includes several significant improvements over the Stolwijk model. To the knowledge of the author, never PCM cloths were utilized in parallel with therapy for fever treatment. The foremost goal of this study is to propose a detailed man thermoregulation model coupled with the melting process within the PCM clothing, using the enthalpy method associated to the dynamic two-node human body thermoregulation model to demonstrate the effects of PCMs in delaying the thermal fever evolution.

BODY DYNAMIC THERMAL BALANCE AND ENERGY EQUATION

Human body thermal balance

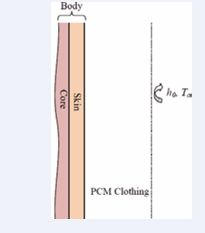

In order to study the transient thermal balance during the sensible energy storage of the clothed body, Figure 1, the dynamic two-node heat transfer model is considered [31,36].

Figure 1: Body PCM clothed model.

In addition, the enthalpy method [27] is used for the transient energy equation in PCM cloths. The dynamic thermal balance can be dressed as follows:

For a seated person, the energy equation modeling the body subject to dynamic thermal balance is:

(1)

where M is the metabolic heat generation, C is the sensible dry heat loss from the skin through clothing, referred to the respiratory heat loss (convective and evaporative),

equals the evaporative heat loss from the skin and

represents the body sensible heat storage. All values are expressed in W/

.

- Metabolic heat generation (M)

The metabolic energy generation can be split to energy production by shivering, and internal organ heat generation,

.

Energy production by shivering

Reduction in skin temperature produces vasoconstriction and shivering. The energy production by shivering is modeled as a function of the mean skin and body core temperatures as [31,36]:

(2)

for skin temperature less than 33.7°C and for core temperatures less than 36.8°C, otherwise, where the deviations terms are set to zero if they became negative. Internal organ heat generation,

The heat generation of fever follows multiple independent afferent and efferent mechanisms depending on the site, nature we study the special case which internal metabolic energy Mint is due to viral thermal fever infection.

is considered. The total metabolic energy generation is:

(3)

- The effects of blood flow on the mean body temperature

For the body two-node model the effects of core and skin

temperatures on blood flow (

) is given by [29]:

(4)

and

and

The mean body temperature substituted in the body dynamic thermal balance equation, Eq. (1) by:

(5)

where, y, is the relative mass of skin to the core:

(6)

- Evaporative heat loss from the skin ( )

When the body becomes hot it loses heat by vasodilation and sweating. The potential evaporation of sweat is the maximum evaporation under the certain ambient conditions. Consequently, when the amount of sweat produced is lower than the potentially evaporating amount of sweat, then all the produced sweat will evaporate, and the corresponding evaporative energy loss can be quantified by [30]:

(7)

Saturated vapor pressure at skin temperature is given by:

(8)

Saturated vapor pressure at air temperature is given by:

where ?: Relative humidity

Emax can be calculated by letting w = 1 in the above equation. Skin wittedness w can be calculated from:

(9)

heat of vaporization of water , r = 2430 kJ kg−1 at 30°C.

The onset of sweating is triggered mainly by the core temperature, , but also high skin temperature values

can cause sweat secretion. Displacement of the brain temperature above the set point results in vasodilatation and sweating. Therefore, the sweat rate (SW, in kg h−1) is modeled as a function of the mean skin and body core temperatures [31]:

(10)

Heat loss from respiration ( )

Heat loss from respiration is by convective heat transfer due to cool air being inhaled, heated to core temperature in the lungs, and heat transferred in exhaled air to the environment. In addition, inhaled air is moistened (to saturation) by the lungs. When exhaled, therefore, there is a mass (heat) transfer from the body core to the outside environment. The total respiratory heat loss equation is, [30]:

(11)

Modeling of the PCM clothing

The transient energy equation in PCM cloths is written, using the enthalpy method [27], as follows:

(12)

The sensible enthalpy, h:

(13)

Using the sensible enthalpy, h, Eq. (13), the equation Eq. (12) is rewritten as follows:

(14)

The second term is a source term which takes into account the latent heat associated with the phase change when it is present. The term f represents the liquid fraction given by:

(15)

The thermophysical properties at the solid liquid interface are evaluated by the following relationships:

(16)

where is the distance between the interface and

the first node of the material ‘+’ and, is the distance between the interface and the first node inside the material ‘-‘.

- Boundary conditions

- Continuity of heat flux and temperatures at the Skin / PCM interface:

(17)

Clothing area factor is taken into consideration when calculating sensible heat loss at the skin using the term, , which is the ratio of the clothed surface area of the body to the nude surface area of the body. Heat flux at the interface between the skin and PCM cloths and can be evaluated as follows:

,

(18)

- Initial conditions

Tsk =33.5 °C, Tc =36.9 °C, f=0 (19)

A standard value of skin surface, AD =1.8m² is used for a 75 kg average man of height 1.73 m. A PCM thickness of em =1 cm used in cloths. The indoor convective heat transfer coefficient, h0 = 8.7 W/m²K

- Numerical method

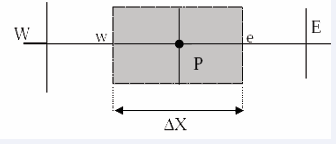

The system of equations obtained is nonlinear and skin temperature Tsk is required to solve this problem iteratively. The initial value of Tsk is used to start the time step calculation for the body dynamic thermal balance. The new temperature value obtained is injected into the expression of the non-linear PCM clothing equations and used for the following calculation loops. In order to solve this system of equations calculation for the body dynamic thermal balance, initial values are required for the body temperatures. These values can be calculated from steady-state models. Since the initial values of mean skin temperature and body core temperature are defined, the storage flow of sensible energy in the body tissue can be evaluated, and through numerical integration over time steps, it is possible to compute the alterations in body temperatures. These new body temperatures constitute the starting values for the next time step. Thus, the thermal state of the human body, characterized by the energy fluxes, the body temperatures, and the sweat rate, can be evaluated. In order to compute the steady-state body temperatures of the model subject at the indoor setting, the stationary energy balance model for individuals [36] has been employed. Thus, the mean skin temperature and the core temperature of the model subject were formed at 33.5 and 36.9°C, respectively. Air temperature: Ta =30°C, Relative humidity: 60%. These body temperatures constituted the starting values at the moment of the model subject’s transition from normal to febrile state. The PCM governing equation and the corresponding boundary conditions are integrated on a uniform mesh using the finite volume technique [35], Figure 2. The finite difference equation is obtained by integrating the PCM equation Eq. (14) on each control volume.

Figure 2: Control volume.

The accumulation term, to the left of the equation Eq. (14), is linearized as follows:

(20)

the first term to the right of the equation Eq. (14), is linearized by:

(21)

Heat flux densities can be linearized as follows:

(22)

and

are the values of the enthalpy at point P at the current instants t and previous instants t-dt, respectively. P, E and W denote the center, the east face and the west face of the control volume.

The discretization of the equation Eq. (14) on each control volume gives the following system of algebraic equations:

(23)

where

(24)

The equation Eq. (23) is solved, for each time step, using the Thomas algorithm (TDMA).

- Update of the liquid fraction

As mentioned before, the energy equation is resolved by the enthalpy method [27]. The source term, , of this equation is the driving element translating the phase change process, and the liquid fraction, f, translates its evolution. Numerically, the value of the liquid fraction is calculated iteratively with the solution of the energy equation. So, in the transport equation in its generally discrete form, Eq. (23), the source term is

. The liquid fraction, f, takes the value 1 in the control volumes located in the liquid region and 0 in the solid region, and it is between 0 and 1 in the control volumes showing the phase change. So after the (k + 1)th numerical solution, the energy equation can be written in the following form:

(25)

If the PCM contained in the control volume (P) is melting, 0

(26)

By subtracting equation (25) from equation (26) the update of the liquid fraction f for the nodes which are changing phase is:

(27)

where, , is a relaxation factor. The update of the liquid fraction is applied to all the nodes. To avoid non-physical values of the liquid fraction, the correction, Eq. (28) following, must be expected immediately after the equation, Eq. (27).

If f>1 then f=1 (liquid), if f<1 then f=1 (solid) (28)

The convergence of the iterations was declared, at each time step, when a criterion based on the energy balance principle was satisfied. A grid and time step refinement was carried out. The time step of dt= 1 seconds and a size grid of n=60 nodes in PCM layer were found to be adequate for all the computations. A self Fortran computer code was developed in order to implement the above numerical scheme.

- Sensible heat loss at the skin through PCM clothing (C)

The density of heat flux at the interface (PCM / skin) equals transfer of heat through skin to clothing, Eq.(18), and approximated by:

(29)

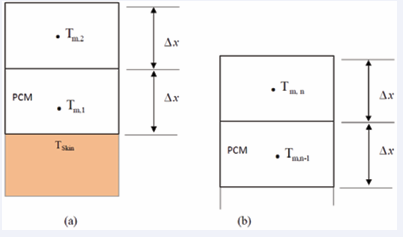

To connect the PCM clothing to body skin thermal field; we integrate the energy equation Eq. (23) over the control volume (a) of Figure 3:

Figure 3: Control volume of PCM cloth in contact with the skin (a) and in contact with the adiabatic face (b).

(30)

Rearranging equation (22) considering expression (21), the obtained algebraic equation is:

(31)

Clothing area factor, , the surface area of the clothed body

, divided by the surface area of the nude body

(32)

The body surface expression is, [37]:

(33)

- East boundary

Integration the energy equation over the control volume (b) of Figure 3 yields:

(34)

Rearranging equation (34), the obtained algebraic equation is:

(35)

RESULTS AND DISCUSSIONS

For mild/moderate fever, the physiological thermoregulation is often enable to insure the core temperature within the set point range (Tc =37°C). Medical intervention (therapy) and simple maneuvers as using cover wetted cold water are frequently used. Cold water absorbs the heat from the skin and sensibly cools the body. The wetted coverage must be removed when it became hot. Phase change materials are able to melt and absorb a high amount of metabolic heat because of their important latent heat of fusion compared to water sensible heat storage. Also the phase change is isothermal which can give a secure skin temperature during the melting of period.

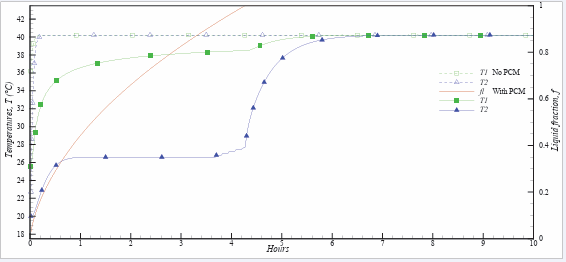

Figure 4 shows the cloths temperature evolution and liquid fraction variation for the case of body with sever thermal fever Tsk =41.1°C. The PCM used is organic RT 25 (Tm =26.6°C, Table 1).

|

Table 1: PCM properties [32-34]. |

||||||

|

Materials |

Name |

Tm |

K |

Ρ |

cp |

?Hf |

|

PCM 1 |

Trimethylolethane |

14.4 |

0.65 |

1170. |

4220 |

1.6 105 |

|

PCM 2 |

E 21 |

21 |

0.43 |

1480 |

680 |

1.5 105 |

|

PCM 3 |

E 23 |

23 |

0.43 |

1475 |

690 |

1.55 105 |

|

PCM 4 |

RT 25 |

26.6 |

0.19 |

785 |

1800 |

2.32 105 |

|

PCM 5 |

CaCl2 -6H2O |

29 |

1.1 |

1710 |

1460 |

1.71 105 |

|

PCM 6 |

E32 |

32 |

0.51 |

1460 |

780 |

1.86 105 |

|

Cloths Without PCM |

Normal Cloths (Cotton) |

- |

0.041 |

25 |

1296 |

- |

|

Body

|

Core |

- |

0.42 |

977 |

2968 |

- |

|

Skin |

- |

0.21 |

1000 |

3760 |

- |

|

For ordinary cloths without PCM, the cloths temperature rises rapidly and is quickly homogenized at T1 = 40.2°C. The ordinary cloths are in contact with ambient air and the excess of heat is carried out from the human body by natural convection and radiation. Figure 4 shows that the heat capacitance of cloths is fully used and stabilized at qs =2.96 kcal which explains the rise of cloths temperature at higher value.

Figure 4: Time wise variations of inner, T1 = Tm,1 , and outer, T2 = Tm,n , cloths temperatures and liquid fraction, f, for PCM and normal clothing.

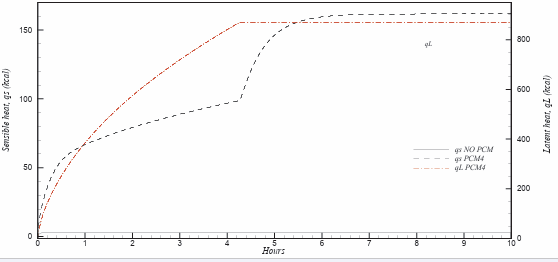

The behavior is different when phase change materials are incorporated in cloths. Also, Figure 4 shows that the temperature near the skin, T1 , rises slowly due to process of phase change when the metabolic energy absorbed to balance the latent heat of fusion instead of the sensible heating of cloths as the case of ordinary cloths as shown in Figure 5.

Figure 5: Sensible and latent heat stored within the PCM and ordinary cloths.

The PCM in contact with skin absorbs the heat and began to melt when its temperature equals melting point, Tm . After about 4 hours and 30 minutes days of the melting phase f = 1, practically all skin energy is accumulated in PCM as latent heat qL =870.54 kcal and a remaining portion of heat is stored as sensible heat, qs = 99.94 kcal, Figure 5. Temperature at skin/PCM cloths interface equals T1 =36.53°C and 38.43°C during the first and third days of wearing PCM cloths, respectively. These values jump to 40.22°C for the case of cloths without PCM. Note that the surface in contact with air of cloths without PCM exceeds 40°C and remarkably greater than the value obtained with the case of PCM cloths (T2 =27.24°C). Phase change materials favorite the sustainable cooling of the body at safe temperature during an important period, more than 4 hours. The use of an organic PCM reduces the Cloths maximum temperature about 4°C. This is a significant gain in terms of temperature for the cooling of the febrile human body. In the following section we discuss the effectiveness of PCM clothing on the core body temperature.

To investigate the thermal response of febrile body to the PCM melting process, 6 different kinds of PCM are incorporated within the cloths, Table 1. The skin, core and mean body temperatures for different instants 1 h, 2 h, 3 h, 4 h and 5 h are given in Table 2.

|

Table 2: Skin, core and mean body temperatures for different PCMs and for different instants. |

||||||||

|

Time |

Temperatures |

Without PCM |

PCM 1 |

PCM 2 |

PCM 3 |

PCM 4 |

PCM 5 |

PCM 6 |

|

1 h |

Tsk |

40.18 |

39.13 |

39.27 |

39.40 |

39.19 |

39.72 |

39.64 |

|

Tb |

40.27 |

39.26 |

39.39 |

39.50 |

39.30 |

39.82 |

39.74 |

|

|

Tc |

41.10 |

40.39 |

40.39 |

40.41 |

39.81 |

40.71 |

40.61 |

|

|

f |

- |

1.00 |

0.74 |

0.69 |

0.44 |

0.83 |

0.45 |

|

|

2 h |

Tsk |

40.18 |

39.35 |

39.46 |

39.565 |

39.38 |

39.82 |

39.75 |

|

Tb |

40.27 |

39.47 |

39.57 |

39.66 |

39.49 |

39.91 |

39.85 |

|

|

Tc |

41.10 |

40.53 |

40.53 |

40.55 |

39.90 |

40.79 |

40.71 |

|

|

f |

- |

1.00 |

1.00 |

1.00 |

0.65 |

0.99 |

0.67 |

|

|

3 h |

Tsk |

40.18 |

39.57 |

39.65 |

39.73 |

39.58 |

39.91 |

39.86 |

|

Tb |

40.27 |

39.68 |

39.76 |

39.82 |

39.68 |

40.01 |

39.96 |

|

|

Tc |

41.10 |

40.68 |

40.68 |

40.69 |

39.95 |

40.87 |

40.81 |

|

|

f |

- |

1.00 |

1.00 |

1.00 |

0.82 |

1.00 |

0.84 |

|

|

4 h |

Tsk |

40.18 |

39.79 |

39.84 |

39.89 |

39.77 |

40. |

39.98 |

|

Tb |

40.27 |

39.90 |

39.94 |

39.98 |

39.87 |

40.10 |

40.07 |

|

|

Tc |

41.10 |

40.83 |

40.83 |

40.84 |

40.37 |

40.95 |

40.91 |

|

|

f |

- |

1.00 |

1.00 |

1.00 |

0.96 |

1.00 |

0.98 |

|

|

5 h |

Tsk |

40.18 |

40.01 |

40.03 |

40.05 |

39.97 |

40.10 |

40.09 |

|

Tb |

40.28 |

40.11 |

40.13 |

40.14 |

40.07 |

40.20 |

40.18 |

|

|

Tc * |

41.10 |

40.97 |

40.97 |

40.98 |

40.86 |

41.03 |

41.01 |

|

|

|

f |

- |

1.00 |

1.00 |

1.00 |

1.00 |

1.00 |

0.82 |

Remind that there are four grades of fever intensity defined as follows: Normal Tc = 37-38°C, Mild/low grade fever 38.1-39°C, Moderate grade fever 39.1-40°C, High grade fever 40.1-41.1 and Hyperpyrexia >41.1°C [22,23]. The most important thermal properties of PCM that can influence the cooling efficacy are the latent heat of fusion and the thermal conductivity of PCM. The main target of the present study is to downward as well as possible the physiological temperature to avoid Hyperpyrexia thermal fever T>41.1°C to High grade fever 40.1-41.1°C, Moderate grade fever 39.1-40°C or, probably, to Mild/low grade fever 38.1- 39°C by wearing suitable PCM cloths. Table 2 data analysis shows that PCM helps to reduces all controlled body temperatures in contrast with subject with normal cloths. For the case of cloths without PCM, body temperature rises drastically from High grade, before achieving the steady state regime, to Hyperpyrexia grade fever at earlier hours of fever symptom. The metabolic heat is convoyed out by evaporation, respiratory and skin heat diffusion to the ambient via cloths. The remaining heat is stored within the body tissue, what leads to its overheating. Convenient therapy intervention must prescript immediately to save the subject life. In-depth analysis of Table data reveals that for the 6 chosen PCMs, PCM No. 4 is the suitable case in view of lowering the body temperature. Indeed, RT 25 PCM is able to keep the core temperature to the Moderate grade fever 39.1-40°C during 3 first hours. The subject temperature increases from 39.8 to 40.8°C between the 3th and the 5th day, during that period, the body remains at the high grade fever. Even though that no therapy is prescripts, the core temperature rises from moderate to high grade fever but never achieves the Hyperpyrexia grade fever, thanks to the melting of phase change material and to the removal of an important amount of the heat from the febrile body. Also, the isothermal behavior of the melting of the PCM plays an important role in shifting the peaks of body temperature.

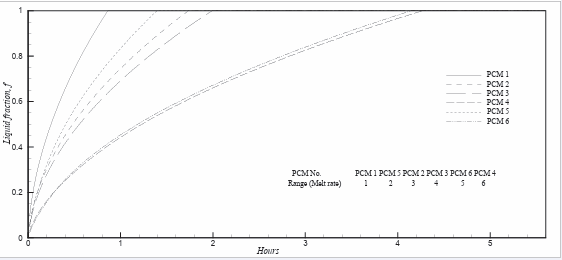

The melting rate varies depending to the PCM thermal properties. Figure 6 clarify that PCM No. 4 melts the last in contrast to PCM No. 1 who melts completely in earlier 1st hour.

Figure 6: Liquid fraction evolution and PCM classification based on their melting rates.

It should be noticed that when the PCM melts completely it loses its capability to absorb the generated metabolic heat. The PCM 4 heat capacity is used during the longest time. Indeed, for the case of PCM No. 4, the liquid fraction f equals 1 after 4 hours and 30 minutes of wearing PCM cloths. If no fever effervescence occurs by lysis, early effective therapy must be prescript to ovoid the subject to fall in the Hyperpyrexia warning zone.

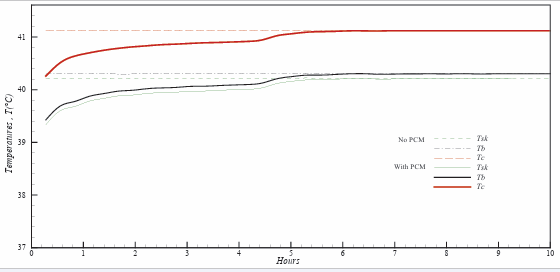

Figure 7 shows the physiological temperatures evolution for PCM no 4 and normal clothing for a febrile subject. Using PCM cloth decreases core temperature less than the case with ordinary cloths.

Figure 7: Body temperature responses to PCM and ordinary cloths.

For the 1st hour, body temperature increases rapidly for ordinary cloths. In contrast to the PCM case where the rate of change in body temperature is lasted by the phase change process and a high energy is removed during the melting period because of activation of the latent heat of fusion of PCM.

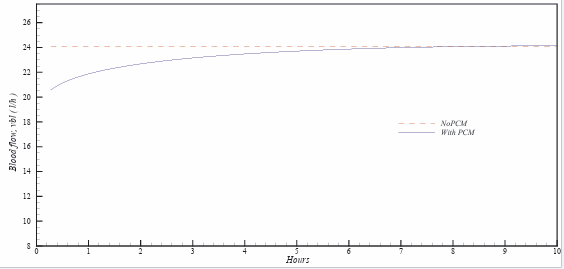

Viral infectious disease can cause a person to develop a fever and the body no longer has that same core temperature of 37°C. Multiple internal body organs are affected when thermoregulation is not working correctly during heat illness. As a result of improper thermoregulation, the heart suffers from an increased burden due to elevations in heart rate and increased cardiac output. Figure 8 and corresponding Table 3 show the effect of PCM on the time wise variation of blood rate, νbl .

Figure 8: Effect of PCM on the time wise variation of blood rate, νbl .

|

Table 3: Blood rate, nbl, for Typical instants. |

||||

|

|

nbl (l/h) |

|||

|

Time |

1h |

2h |

3h |

4h |

|

Without PCM |

24.1 |

24.1 |

24.1 |

24.1 |

|

PCM No. 4 |

21.8 |

22.66 |

23.15 |

23.4 |

It is clearly demonstrated that blood rate increases from 21.8 l/h to 23.4 l/h for febrile subject wearing PCM cloths (PCM no. 4), respectively, during the first 4 hours of viral infection illness. As time collapse, blood rate rises asymptotically for the PCM cloths case to become constant at 24.1 l/h. For the PCM case, it is clear that, during the studied period, the blood rate rises but remains always less than the levels obtained with normal clothing case. It’s recommended to be dressed in suitable PCM clothing to break the rise of the blood rate in parallel with an effective fever therapy.

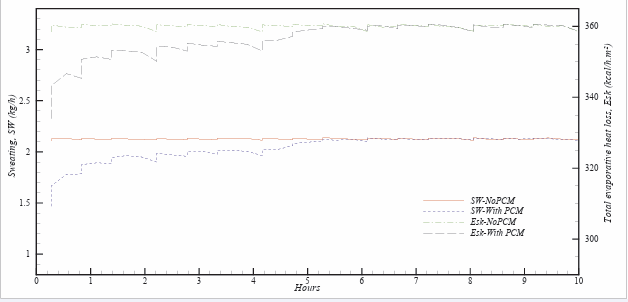

Figure 9 sketches the variations of water loss by sweating and evaporative heat loss for the base and the PCM cases. Viral thermal fever provokes improper thermoregulation. It’ll automatically send signals to the skin, glands, muscles, and organs.

Figure 9: Time wise evolution of the sweat rate and evaporative heat loss for the base case and for cloths with PCM.

Due to abnormal metabolic rate increase, the body’s temperature will rise, which causes the hypothalamus to send signals to the cells of the skin that produce sweat. Sweating is an approach that the body uses to relax itself down. Because the body’s temperature rises and giving ambient temperature and air humidity conditions, sweat is evaporated. The body loses a crucial quantity of water. As a result, the many organs suffer from intravascular dehydration. Pulmonary vasodilation can commence because of the dehydration. Very important finding are presented in Figure 9. Curves analysis reveals that the febrile body loses less water when it wears the PCM cloths. Indeed, for normal cloths and PCM cloths, respectively, the body evacuates sweat quantity of 2.12 l/h, 1.94 l/h at 2 hours and these quantities collapse to 2.13 l/h after about 5 hours. Nolte that, the oscillatory behavior of sweating heat curves is due to the fact that when the body evacuates sweat, the expelled water evaporates and incites the self-cooling of the skin and then the sweat production decrease temporally. Because of the continuous metabolic heat generation within the body and due to the absence of an effective therapy, core temperature increased leading to new cycle of sweating followed with water evaporation.

CONCLUSION

The PCM capacity to cool febrile bodies is studied. The human two-node thermoregulation model coupled to the enthalpy method has been developed. For moderate fever, physiological thermoregulation is frequently activated to ensure a core temperature in the set point (Tc = 37°C). For severe illnesses, such as malaria and COVID 19 infections, different PCM uniforms are tested to delay the body overheating. It has been found that phase change materials with higher latent heat of fusion and a suitable freezing point reduce the maximum cloths temperature by about 4°C less than the value obtained compared to cotton fabrics. PCM cloths provide a safe skin temperature during the melting period and extract a large amount of heat, more than 900 kcal, from the body due to the high latent heat of fusion compared to cotton fabrics that store less than 3 kcal. Analysis of the skin temperature and core temperature responses to PCM fusion shows that PCM contributes to sensible reduction of body temperatures about 1°C compared to subject with normal cloths. A suitable PCM is able to maintain the core temperature at moderate grade fever for about 3 hours. The drop off the latent heat capacity during melting process increases the body temperature of moderate to high grade fever. If no fever effervescence occurs by lysis, effective early treatment should be prescribed to prevent the body from falling into the hyperpyrexia warning zone. In the case of PCM, the febrile body loses less water and the blood flow level increases but always remains lower than the amount achieved with normal clothing. It is recommended to wear appropriate PCM clothing to avoid further complications, in addition to effective treatment for fever.

REFERENCES

6. Outlast. Retrieved June 5, 2018. 2015.

7. Colvin DP, Bryant YG. Microclimate cooling garment. US Patent.1995; 5: 415.

17. World health organization. Integrated management of childhood illness. 2018.

18. World health organisation. Guidelines for the treatment of malaria. Cite this article 2016.

30. ASHRAE 1997. Thermal comfort, ASHRAE Handbook of Fundamentals. Chapter 8, Atlanta, USA.